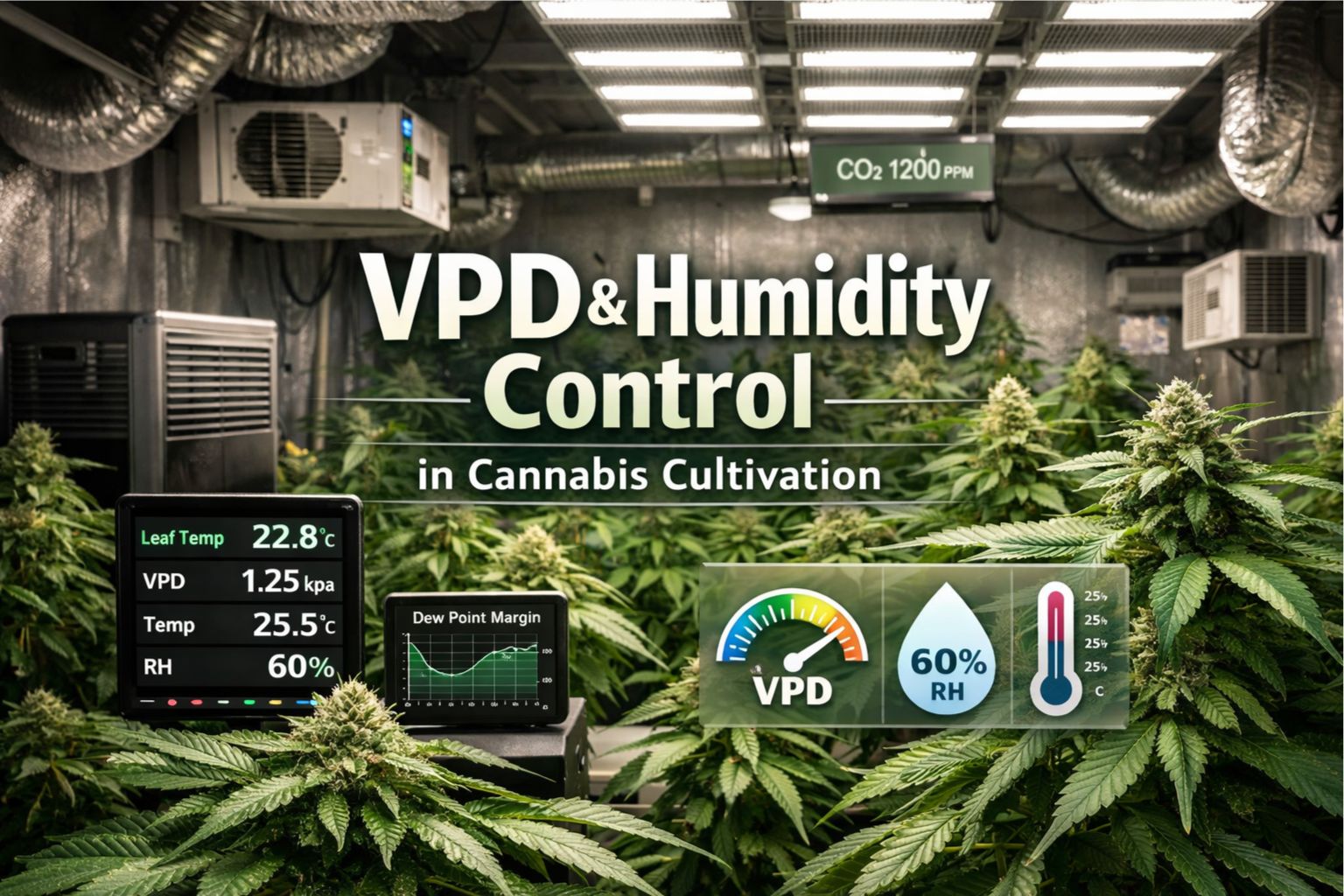

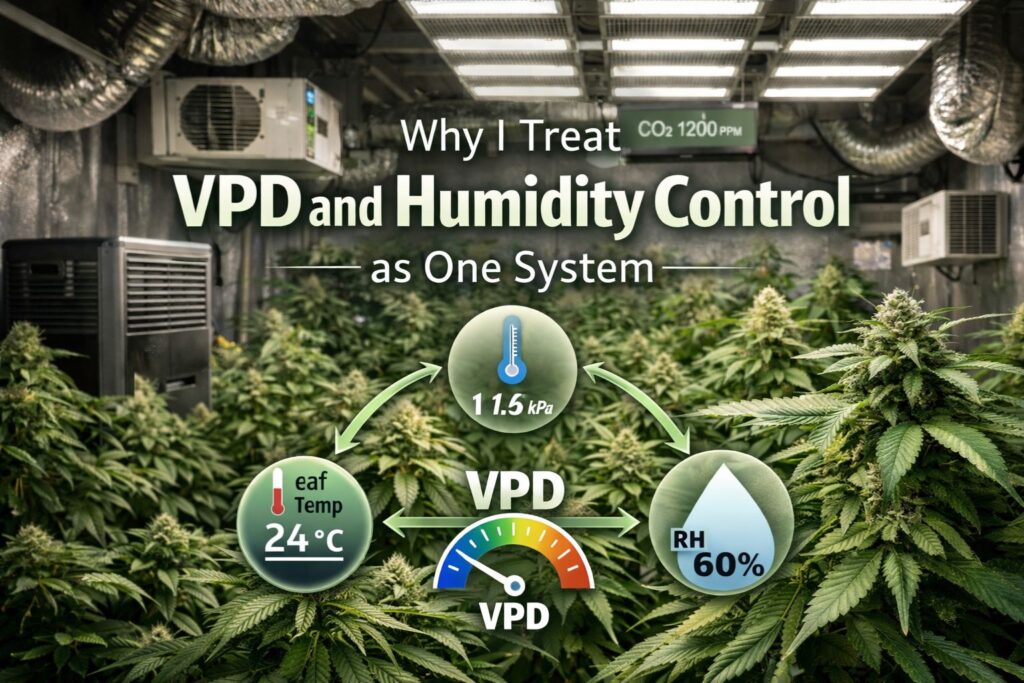

Why I Treat VPD and Humidity Control as One System

I used to manage my room by chasing a single number on a hygrometer. If relative humidity looked “right,” I assumed the plants would follow. In reality, my cannabis, marijuana, and weed crops kept giving me mixed signals: fast drybacks one week, slow uptake the next, and occasional leaf-edge burn that I blamed on nutrients.

The fix was not a new bottle or a new light. It was learning VPD and Humidity Control as one connected system. VPD is about how eager the air is to pull water from a leaf. Humidity is the knob you turn, but temperature, airflow, leaf temperature, and irrigation habits decide whether that knob actually does anything useful.

Once I put VPD and Humidity Control at the center of my routine, three things improved quickly:

- My watering became more consistent because the plant’s demand stopped swinging.

- My room smelled cleaner in late flower because moisture stopped lingering in the canopy.

- My drying room became predictable, which improved bag appeal and burn quality.

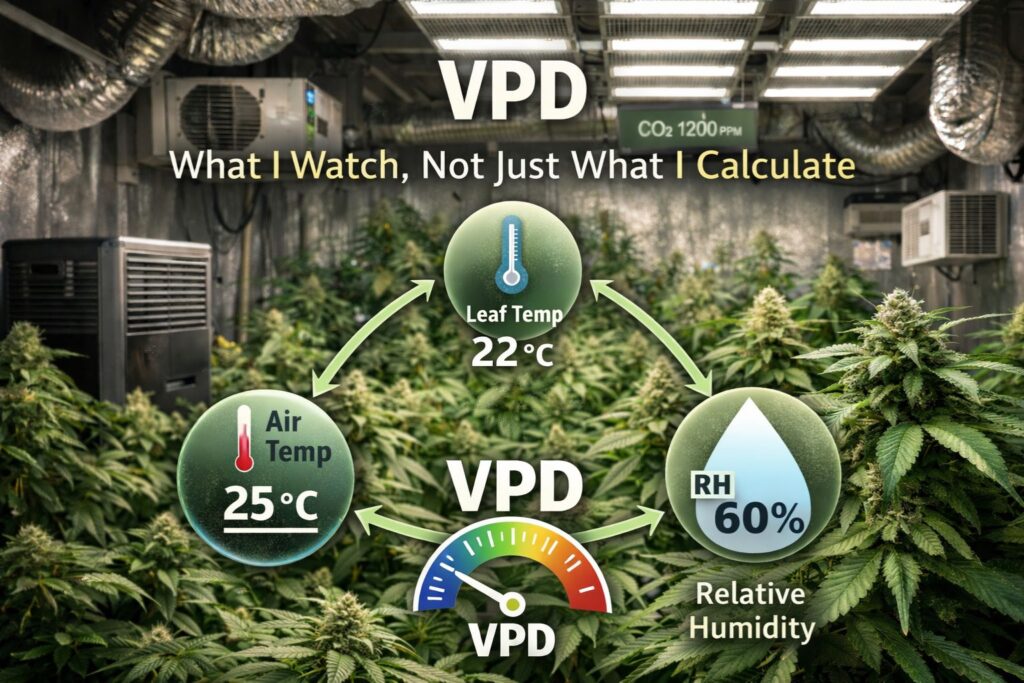

VPD (What I Watch, Not Just What I Calculate)

VPD is often explained with charts and equations, but you can grow well if you understand the idea: warm air can hold more moisture than cool air. When the air is far from “full,” it can pull moisture from leaves faster. When it’s closer to “full,” it pulls moisture more slowly.

That is why VPD and Humidity Control must include leaf temperature, not only air temperature. Under modern LEDs, leaves can run cooler than the room air. If your leaf is cooler, the plant experiences a drier pull than your sensor suggests. That’s why I keep leaf checks in my weekly routine and use canopy microclimate mapping to confirm the room is behaving the way the plants are.

My quick leaf check routine

I use an infrared thermometer and take three readings for leaf temperature tracking:

1) A top leaf directly under the brightest zone

2) A mid-canopy leaf in average light

3) An edge leaf near an intake or doorway

I write down the leaf-to-air difference. If that delta shifts, my VPD and Humidity Control targets shift too.

Tools and Sensor Placement That Make VPD and Humidity Control Work

If your readings are wrong, your decisions will be wrong. I’m not picky about brands, but I am picky about placement and consistency.

Canopy microclimate mapping without buying ten sensors

For canopy microclimate mapping, I place at least two temperature/RH sensors:

- One at canopy height, shaded from direct light and not in a humidifier stream

- One across the room near return air or the opposite corner

Then I verify with my own legs: I walk the room, feel for dead zones, and use canopy microclimate mapping notes to adjust fans and ducting. This simple canopy microclimate mapping habit finds problems early, like a corner that runs damp after lights out.

Why I always track a dew point safety margin

The dew point safety margin is my “condensation alarm.” If surfaces get cold enough, moisture can condense even when the room average looks safe. The dew point safety margin matters most at night, near exterior walls, and around metal ducting.

I keep a dew point safety margin by avoiding big temperature drops and by controlling the nighttime RH swing. When I ignore the dew point safety margin, I get wet spots on walls and a higher chance of disease pressure.

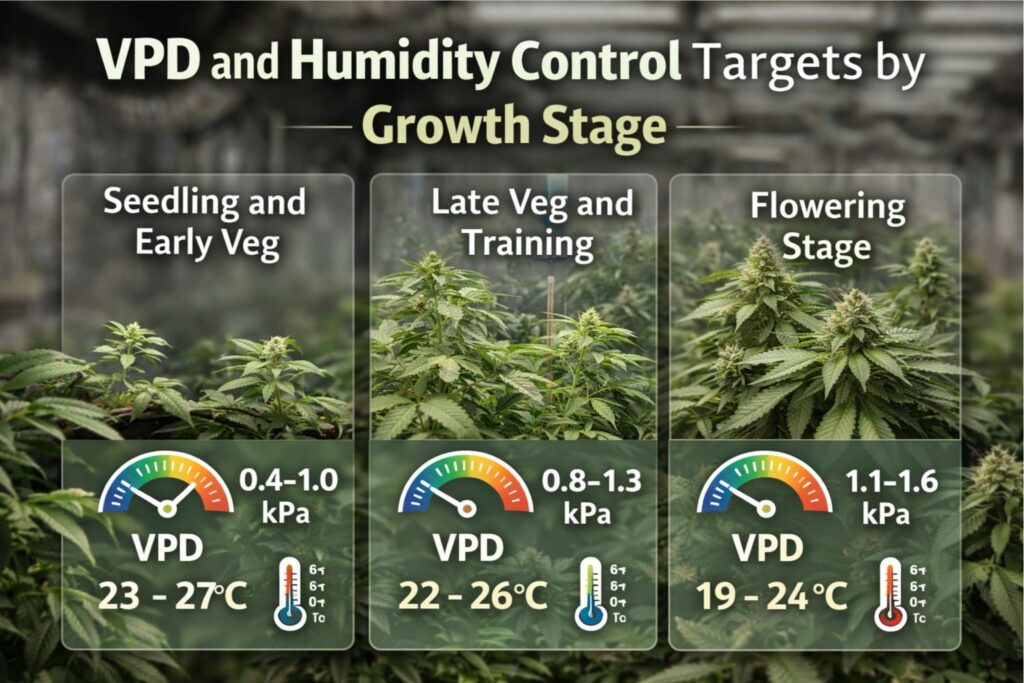

VPD and Humidity Control Targets by Growth Stage

I’m not going to pretend there is one perfect number for every room. Genetics, pot size, medium, and airflow change what “good” looks like. But there are patterns that repeat.

Seedling and early veg

In early growth, I prioritize gentle demand. I want roots building without forcing the plant to drink too hard.

What I focus on:

- Stable VPD and Humidity Control day to day

- A safe dew point safety margin during cool nights

- Light airflow that doesn’t dry the surface too quickly

If I see slow growth, I look at irrigation frequency under VPD. When the air is too dry, small plants can stall because the root zone stays wetter while leaves lose moisture faster than they should.

Late veg and training weeks

This is when I dial in structure, whether I’m working with a tall sativa-leaning plant, a squat indica-leaning plant, or a balanced hybrid.

My priorities:

- Canopy microclimate mapping after training sessions

- A tighter dew point safety margin because leaf mass is increasing

- Matching irrigation frequency under VPD to the bigger canopy

If I enrich CO2, I watch CO2 and VPD interaction closely. CO2 and VPD interaction shows up as faster photosynthesis only when the plant can move enough water. If VPD is too low, stomata may not behave the way you expect, and CO2 and VPD interaction becomes a source of confusion rather than a benefit.

Early flower (stretch and flower set)

Early flower is when sealed rooms reveal whether your equipment is truly sized for the job. Stretch adds leaf area fast, and the room can jump from easy to difficult in a week.

This is where sealed room moisture load becomes the whole story. Sealed room moisture load is the total water the plants and medium are putting into the air each day. If sealed room moisture load exceeds what your dehumidifier can remove, humidity climbs no matter what your setpoint says.

I handle this by:

- Increasing airflow mixing (not blasting the canopy)

- Adjusting irrigation frequency under VPD as demand changes

- Watching the nighttime RH swing so I don’t wake up to a wet room

Mid to late flower (bulk and risk management)

In late flower, I treat mold risk scoring like brushing my teeth. It’s not dramatic, it’s routine. Mold risk scoring is how I keep myself honest when the canopy is thick and the buds are stacking.

My mold risk scoring checklist looks like this:

- Is the dew point safety margin still safe at lights out?

- Did sealed room moisture load increase after I changed irrigation?

- Are there any stagnant zones found by canopy microclimate mapping?

- Did I time defoliation timing for airflow correctly?

Defoliation timing for airflow matters most when the interior becomes shaded and humid. If I strip too early, I slow growth. If I strip too late, airflow can’t reach problem areas. I plan defoliation timing for airflow around the point when flower sites are clearly formed and the plant is done with the most aggressive stretch.

I also keep a close eye on intake air conditioning strategy. If I’m pulling outside air, intake air conditioning strategy changes with seasons. In humid months, intake air conditioning strategy often means pre-drying intake air or limiting intake during the wettest hours.

Humidifiers, Dehumidifiers, and Controllers (What I’ve Learned the Hard Way)

Equipment selection is where many new growers burn money. The room is not a static box. As plants grow, sealed room moisture load rises. As you increase light, transpiration changes. As seasons change, intake air conditioning strategy changes.

Sizing based on sealed room moisture load

I estimate sealed room moisture load by tracking:

- Daily irrigation volume

- Runoff behavior (or lack of runoff)

- Room temperature trends

- Humidity recovery time after irrigation

If humidity spikes and takes hours to recover, that’s a sealed room moisture load problem, not a “bad sensor” problem.

Where I place equipment

Placement is half the battle.

- Humidifier placement: I keep it low, aimed into airflow, never directly at canopy.

- Dehumidifier placement: I place it where it can pull mixed air, not trapped air.

- Controller probes: I keep them away from direct streams so readings represent the room.

This supports VPD and Humidity Control because the controller can’t correct what it can’t accurately measure.

Avoiding a nasty nighttime RH swing

The nighttime RH swing is a common trap. Lights go off, temperature drops, and humidity climbs. If you don’t plan for that nighttime RH swing, you can spend all night near condensation.

My fixes:

- Reduce the size of temperature drops at lights out

- Maintain airflow mixing after lights out

- Use dehumidification that is sized for sealed room moisture load

Medium Choice and Irrigation Habits That Affect VPD and Humidity Control

Your medium and irrigation schedule feed the air. Soil, coco, and hydro each behave differently.

Dryback targets in coco and why they change with VPD

In coco, dryback targets in coco are powerful, but only when they match the environment. If VPD is high and you push aggressive dryback targets in coco, you can stress plants and chase symptoms with nutrients.

I set dryback targets in coco based on stage:

- Early veg: moderate drybacks that keep roots expanding

- Late veg to early flower: tighter control to support rapid growth

- Late flower: steady drybacks that avoid big swings

Dryback targets in coco also connect to irrigation frequency under VPD. When VPD rises, plants drink faster, so irrigation frequency under VPD often increases. If you increase irrigation frequency under VPD without enough dehumidification, sealed room moisture load goes up.

Soil and hydro notes

With soil, I watch surface evaporation and airflow, because a wet top layer can add moisture to the room and affect mold risk scoring.

With hydro, I cover exposed water surfaces when possible because evaporation can add to sealed room moisture load.

Seed Buying Decisions That Make Environment Easier

I’m careful about how I choose seeds because genetics can make environmental control easier or harder.

When I shop, I think about:

- Plant structure and how it affects canopy microclimate mapping

- Flower density and how it affects mold risk scoring

- Timing and how it affects defoliation timing for airflow

Feminized seeds, autoflowers, and planning

Feminized seeds help with planning because you’re not budgeting space and time for removing males. Autoflowers can be convenient, but they can also be less forgiving if VPD and Humidity Control swings during their fast transitions.

I also consider expected height and stretch. Tall plants can create warm and cool layers, so canopy microclimate mapping becomes more important.

Indica, sativa, and hybrid structure

In my experience, some sativa-leaning plants grow taller and airier, while some indica-leaning plants grow shorter with tighter flower clusters. A balanced hybrid can land anywhere in between. None of this is absolute, but structure changes how much defoliation timing for airflow matters and how strict my mold risk scoring needs to be.

Seed banks, shipping, and practical expectations

When comparing seed banks, I look for clear information, stable communication, and realistic shipping timelines. Shipping conditions can vary by region and season, so I avoid making time-critical plans around the fastest possible delivery.

Also, regional rules vary a lot. I don’t give legal advice, but I do recommend learning local requirements before you order or start a grow.

My Weekly Routine for VPD and Humidity Control (Simple and Repeatable)

This is my practical routine. It keeps me from overreacting to a single reading and helps me catch problems early.

Daily checks (10 minutes)

- Confirm temperature and RH are stable at canopy height

- Note any unusual nighttime RH swing patterns

- Do a quick mold risk scoring pass: smell, airflow, damp corners

Twice-weekly checks (20 minutes)

- Leaf temperature checks and a quick dew point safety margin review

- Canopy microclimate mapping walk-through and fan adjustments

- Review irrigation frequency under VPD and compare to dryback targets in coco if I’m in coco

Weekly checks (30–45 minutes)

- Re-evaluate sealed room moisture load based on irrigation changes

- Verify intake air conditioning strategy matches current weather patterns

- Confirm CO2 and VPD interaction is stable if I’m enriching

Post-Harvest: Drying and Curing With VPD and Humidity Control

Most growers focus on environment during growth, then “wing it” during drying. I used to do that too, and it cost me aroma and texture. Now I treat the dry as a continuation of VPD and Humidity Control.

Dry room climate setup

My dry room climate setup aims for slow, controlled moisture release. The biggest mistake I see is drying too fast because the room is too warm and too dry.

I keep:

- Stable temperature

- Stable RH

- Gentle airflow that does not point directly at hanging branches

Post-harvest moisture equalization (why it matters)

Post-harvest moisture equalization is the step that made my cure more consistent. After the initial dry, moisture inside the flower moves outward. Post-harvest moisture equalization helps prevent the outside from becoming crispy while the inside is still wet.

My post-harvest moisture equalization routine:

- After hanging, I let trimmed material rest in a controlled environment before final storage

- I avoid huge humidity swings in containers

- I keep monitoring for odor changes that could suggest excess moisture

Post-harvest moisture equalization also reduces the chance of problems during curing. If you skip post-harvest moisture equalization, you can trap moisture inside and create off smells.

FAQ: Common Google-Style Questions I Hear From Growers

What VPD should I run in late flower for cannabis?

I focus on stable VPD and Humidity Control with a strong dew point safety margin. Late flower rewards consistency more than chasing an aggressive number.

Why does my humidity spike right after watering?

That’s usually sealed room moisture load. More irrigation and more evaporation means more moisture in the air. Adjust irrigation frequency under VPD and make sure dehumidification can keep up.

How do I prevent moisture issues without over-drying the room?

Use mold risk scoring and canopy microclimate mapping. If the room is mixed well and the dew point safety margin stays safe, you don’t need to run extreme dryness.

Does CO2 change my VPD targets?

CO2 and VPD interaction can change how plants behave. If you enrich CO2, keep VPD and Humidity Control stable and watch leaf posture and watering demand.

What’s the fastest way to improve my environment without remodeling?

Start with canopy microclimate mapping, then refine intake air conditioning strategy and equipment placement. Small airflow and probe changes often make a bigger difference than new gear.