How I learned to use TAC without chasing numbers

I used to shop genetics and plan feeds the same way a lot of growers do: I looked at the biggest THC number on the label, nodded, and moved on. Then I started comparing my own harvests to lab results from different facilities, and the cracks showed. Two jars from the same plant could feel noticeably different after cure. A cultivar that “tested high” could still smoke flat if I rushed the dry. And I kept seeing a bigger number than THC showing up on Certificates of Analysis: TAC.

This post is my hands-on grower’s take on TAC in Cannabis: what it means, how labs calculate it, how it relates to real-world potency, and why it matters when someone is choosing products for symptom management. I’ll keep the discussion practical, grow-room focused, and honest about limitations. Lab metrics can guide decisions, but they do not replace personal tolerance, clinician guidance, or local regulations.

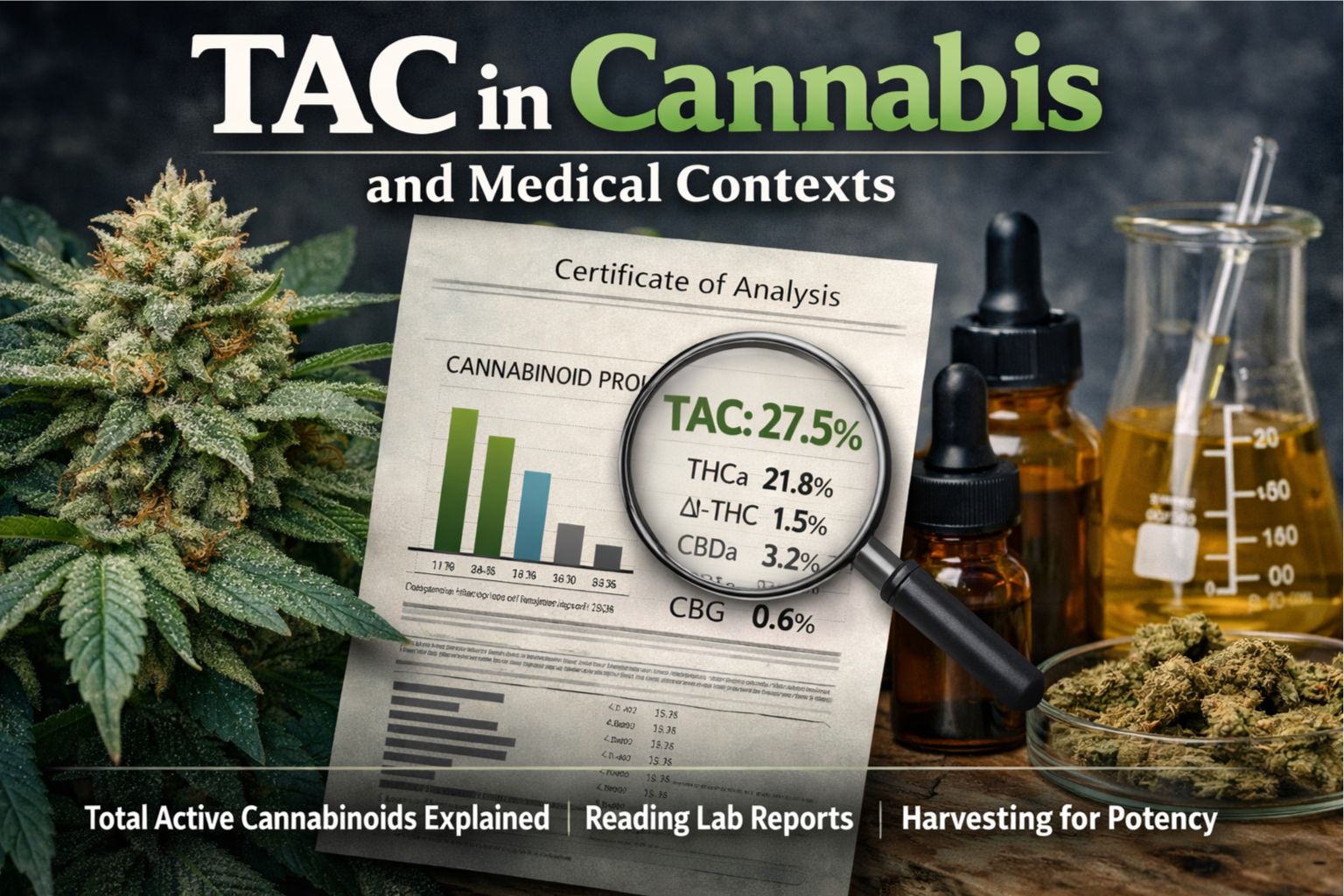

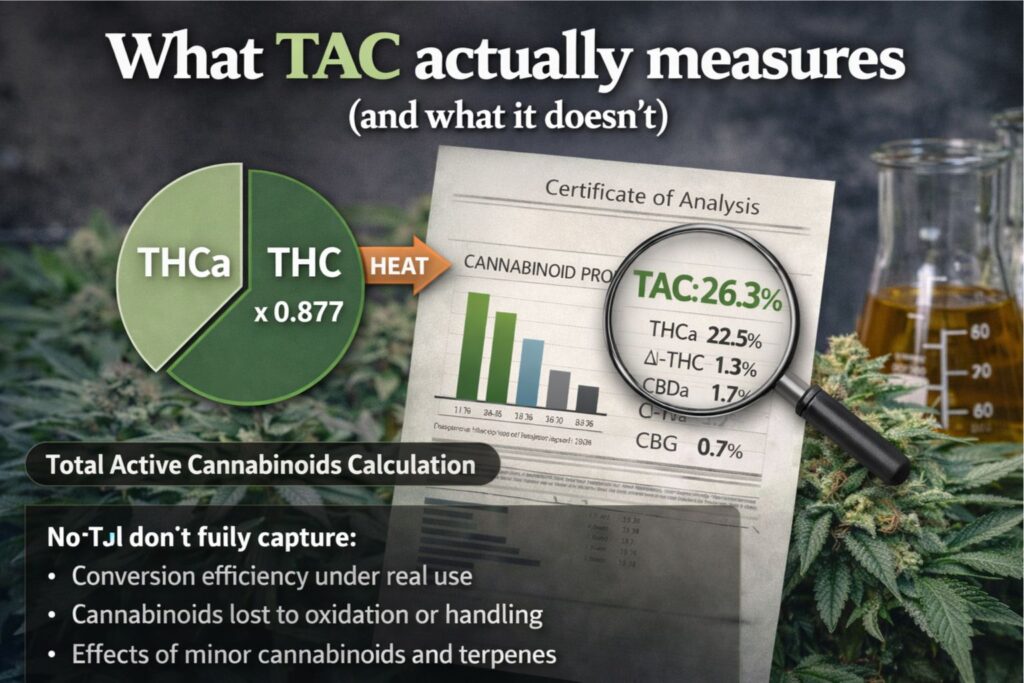

What TAC actually measures (and what it doesn’t)

TAC is commonly used as shorthand for total active cannabinoids. In most lab reports, it’s an estimate of the total cannabinoids available after conversion of acidic cannabinoids into their neutral forms (primarily through heat). In practice, TAC is built from a total active cannabinoids calculation that starts with the plant’s acidic cannabinoids, then applies a conversion factor to approximate how much neutral cannabinoid could be produced after decarboxylation.

In my own notes, the first place TAC helped was with honesty. Fresh flower is rich in THCa, not THC. If I’m comparing batches, the number labeled THC alone often under-represents what a consumer experiences after combustion or vaporization. That’s where TAC in Cannabis can be useful: it’s a standardized attempt to describe potential cannabinoid availability.

At the same time, TAC is not a magic “strength” score. It does not fully capture:

- How efficiently cannabinoids convert under real use (vape temps, combustion, edible decarb)

- How much cannabinoid is lost to oxidation or handling

- Effects driven by aroma compounds, especially minor cannabinoids and terpenes

- How a person responds to different cannabinoid ratios and delivery methods

If you remember one thing, remember this: a good TAC number can still accompany mediocre flower, and a modest TAC number can still deliver a great experience when the cure and terpene preservation are on point.

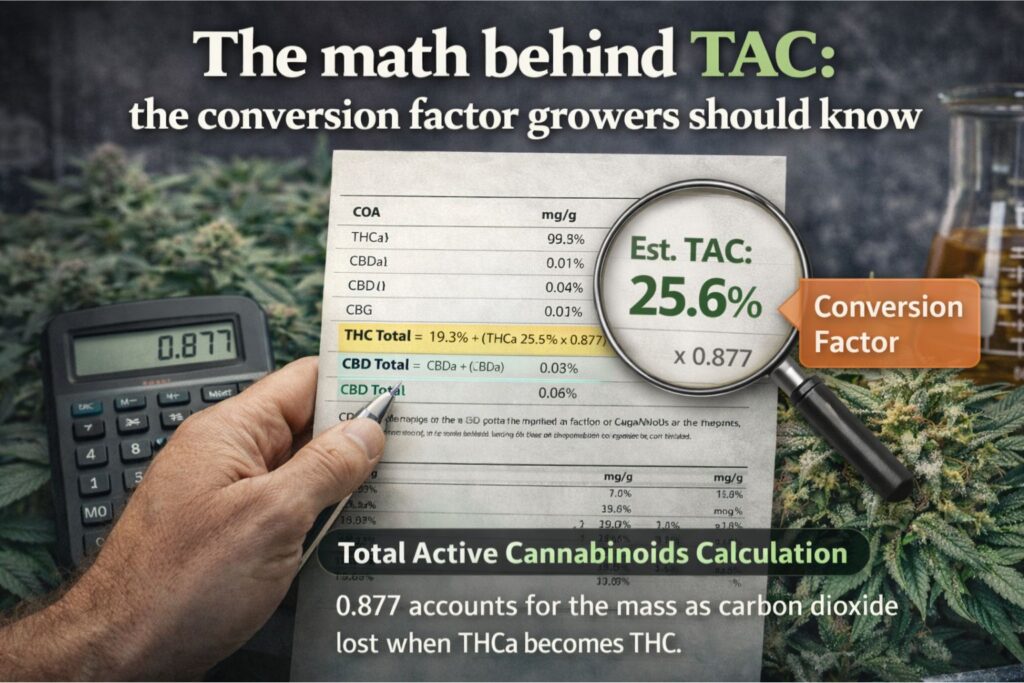

The math behind TAC: the conversion factor growers should know

Most COAs list cannabinoids in milligrams per gram (mg/g) or percent (%). The backbone is the total active cannabinoids calculation, often expressed as:

- Total THC = THC + (THCa × 0.877)

- Total CBD = CBD + (CBDa × 0.877)

The 0.877 factor accounts for the mass lost as carbon dioxide when THCa becomes THC. Many labs then sum total THC, total CBD, and sometimes other converted cannabinoids to estimate TAC. Not every lab includes the same set of compounds in TAC, which is why I always review the individual line items before trusting a single headline number.

When I do a quick sanity check, I’ll compare:

- The reported TAC number

- The lab’s listed “Total THC” and “Total CBD”

- Whether CBG/CBGa, CBC, THCV, or other minor cannabinoids are included

If a lab uses tac vs thc labeling on a product, I want to know whether TAC is simply “Total THC” renamed or whether it’s a broader sum of cannabinoids. That difference matters when you’re comparing flower to concentrates or when you’re trying to predict effects.

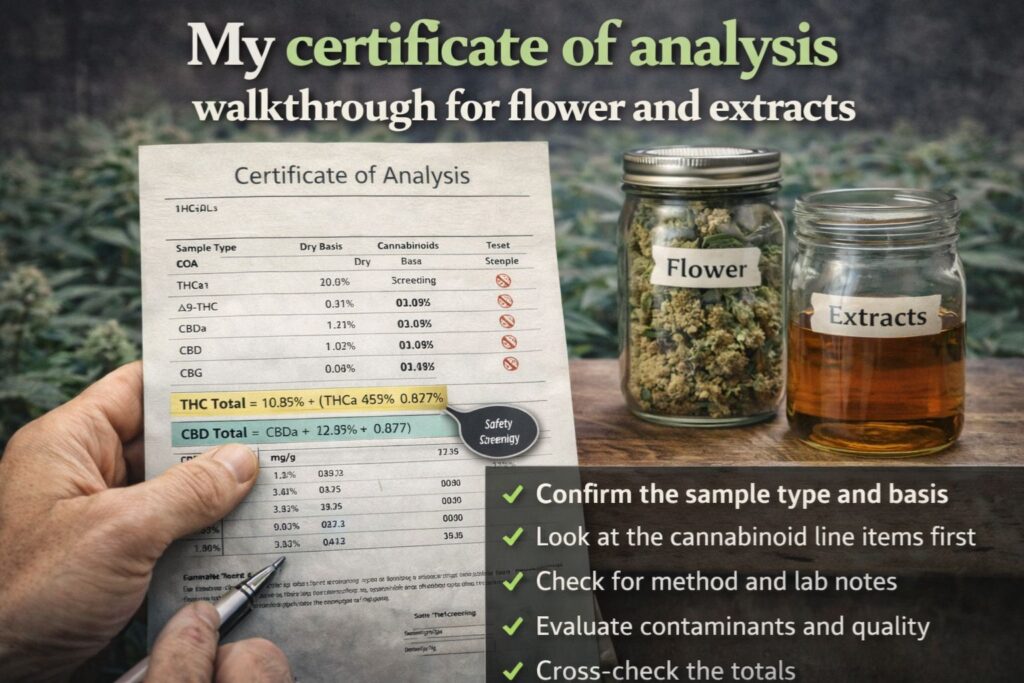

My certificate of analysis walkthrough for flower and extracts

I treat a certificate of analysis walkthrough like checking the instrument panel before a long drive. I’m not expecting perfection, but I want to spot red flags early.

Here’s how I read a COA, step by step:

Step 1: Confirm the sample type and basis

Is it flower, pre-roll, extract, distillate, or edible? Is the result on an as-received basis or dry weight basis? This affects tac percentage interpretation because moisture varies and concentrates behave differently.

Step 2: Look at the cannabinoid line items first

I scan THCa, THC, CBDa, CBD, CBG/CBGa, CBC, and any varin cannabinoids (like THCV) when available. This is the raw material of cannabinoid profile reporting.

Step 3: Check for method and lab notes

Methods like HPLC (for acids) versus GC (which decarbs in the injector) change how results appear. I prefer HPLC when I want to see acids clearly.

Step 4: Evaluate contaminants and quality markers

Even if you’re here for TAC in Cannabis, the safety parts matter:

- Microbial screening

- Residual solvents (for extracts)

- Heavy metals

- Pesticide panels

Step 5: Cross-check the totals

I do my own quick total active cannabinoids calculation if the totals look suspicious. If the lab’s totals don’t match the line items within reasonable rounding, I assume the “headline” number is more marketing than measurement.

This certificate of analysis walkthrough takes me two minutes once you’ve practiced it, and it keeps you from chasing numbers that aren’t comparable.

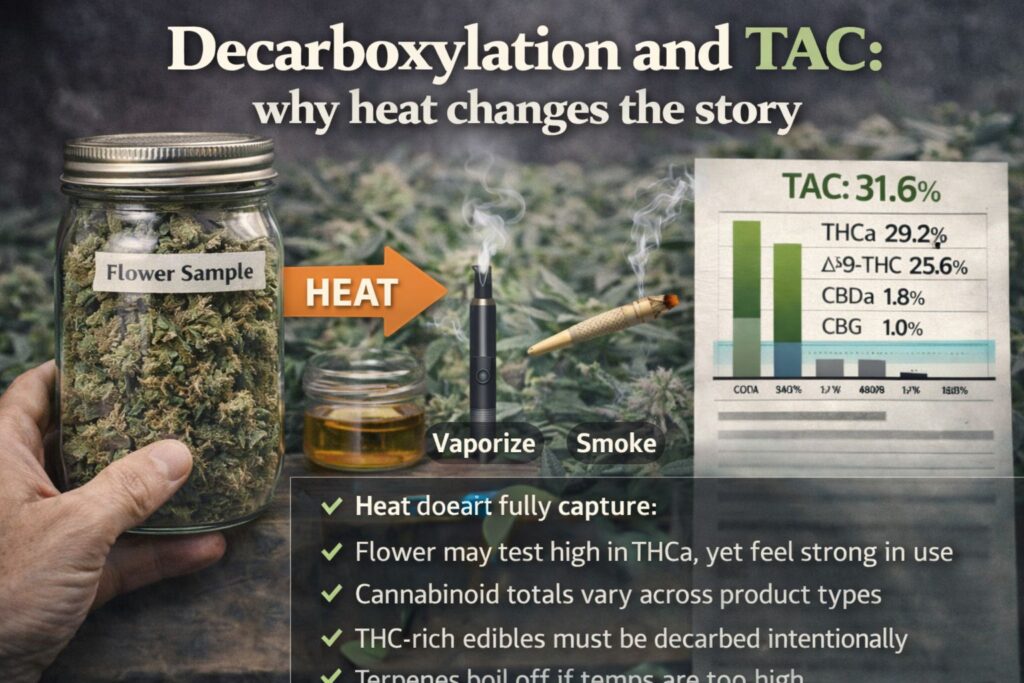

Decarboxylation and TAC: why heat changes the story

Decarboxylation and tac is the pivot point between what’s in the jar and what’s active in use. A flower sample can test with high THCa and low THC, yet still deliver a strong effect when smoked or vaporized because THCa converts to THC with heat.

As a cultivator, I care about decarboxylation and tac for two reasons:

Product comparisons across formats

Concentrates may already contain higher THC relative to THCa depending on processing. If you compare a rosin COA to a flower COA, TAC can help normalize the discussion, but only if you understand what is being summed.

Planning for edibles and infusions

When I make infusions, I decarb intentionally. Here’s what has worked for me to balance conversion with terpene preservation:

- Break up material loosely, don’t powder it

- Use an oven thermometer, not the dial

- Aim for steady heat, not spikes

- Cool in a sealed container when possible

Different inputs and equipment vary, so I treat this as a repeatable process: same dish, same load, same time, then compare results over time.

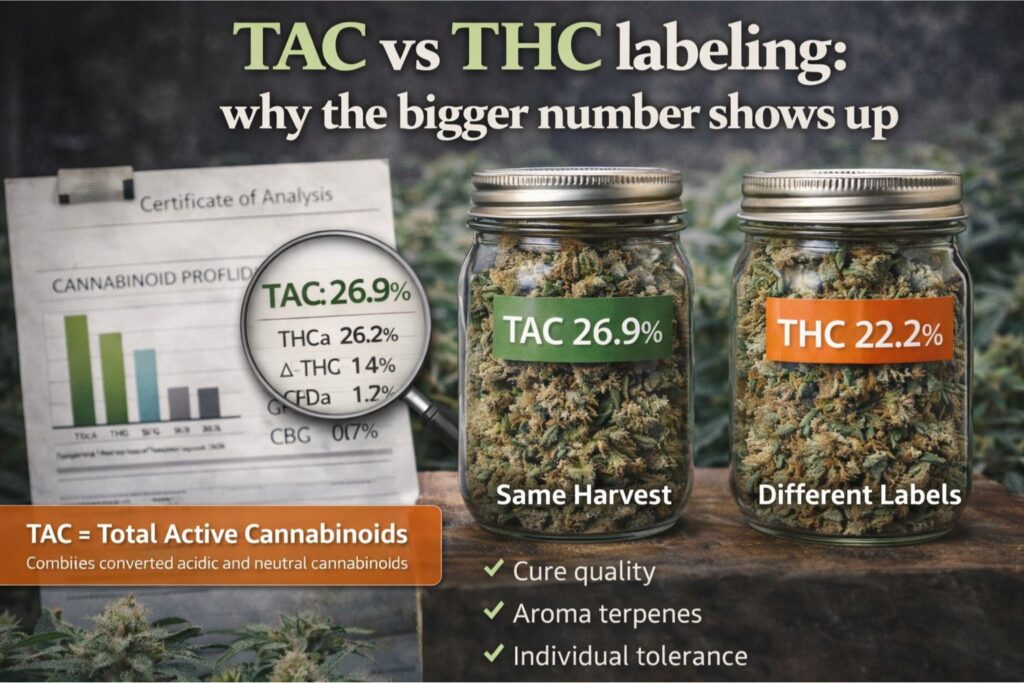

TAC vs THC labeling: why the bigger number shows up

In dispensaries and online catalogs, tac vs thc labeling is often used because TAC tends to be higher than THC alone, especially for flower. But the bigger number isn’t automatically “better.” If two flowers are both well-grown, the difference between 24% and 27% TAC often matters less than the quality of the cure, the freshness of the terpenes, and the individual’s tolerance.

I’ve seen growers chase a top-line number at the cost of plant health. Pushing late-flower stress too far can reduce overall quality. I’ve also seen a balanced chemotype with modest TAC outperform a higher-TAC batch in perceived effects because the minor cannabinoids and terpenes were intact.

If you’re shopping, treat tac vs thc labeling like you’d treat horsepower on a car ad: useful, but incomplete without context.

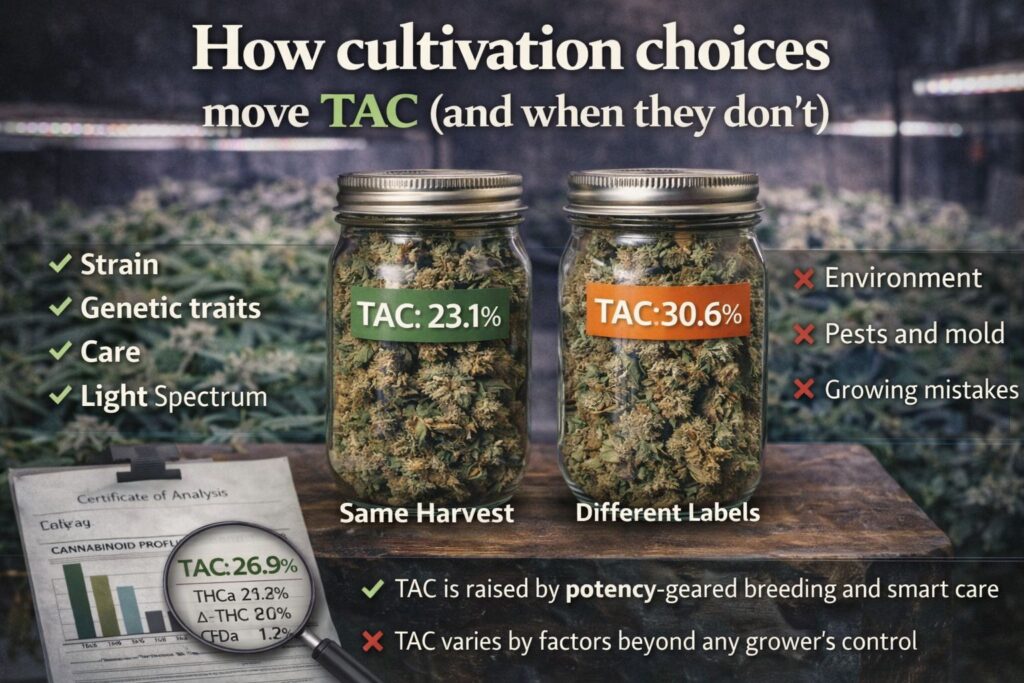

How cultivation choices move TAC (and when they don’t)

Genetics sets the ceiling, but cultivation sets whether you get close to it. When I’m trying to improve TAC in Cannabis outcomes, I think in terms of consistency rather than a single peak number.

Environment ranges I rely on

These are general ranges I use as starting points indoors. Every room differs, so I adjust based on plant response.

- Temperature: 24–28°C lights on, 19–22°C lights off

- Relative humidity: 55–65% in veg, 45–55% in mid flower, 40–50% late flower

- VPD: roughly 0.9–1.2 kPa in veg, 1.2–1.5 kPa in flower (adjust for cultivar)

- PPFD: 600–900 µmol/m²/s in flower for many hybrids, increased gradually with healthy plants

- Photoperiod: 18/6 for veg; 12/12 for flowering cultivars; stable light schedule with no leaks

I’ve learned that chasing extreme PPFD without supporting nutrition and root health is a fast path to leaf stress and stalled resin production.

Feeding and substrate notes

I run both living soil and recirculating hydro depending on the project. The biggest lesson across both: consistent root-zone conditions create consistent cannabinoid profile reporting from run to run.

- In hydro, I track EC and pH daily and keep swings small. Rapid swings can show up as late-flower stress.

- In soil, I focus on aeration, microbial activity, and avoiding overwatering. Root oxygen is potency insurance.

Integrated pest management

Pests and mold pressure can force early harvest, which directly impacts harvest timing for cannabinoid potency. I prefer prevention:

- Clean intake filters and keep negative pressure

- Scout undersides of leaves weekly

- Use beneficial insects early when appropriate

- Avoid late-flower foliar sprays unless necessary

Harvest timing for cannabinoid potency: my practical approach

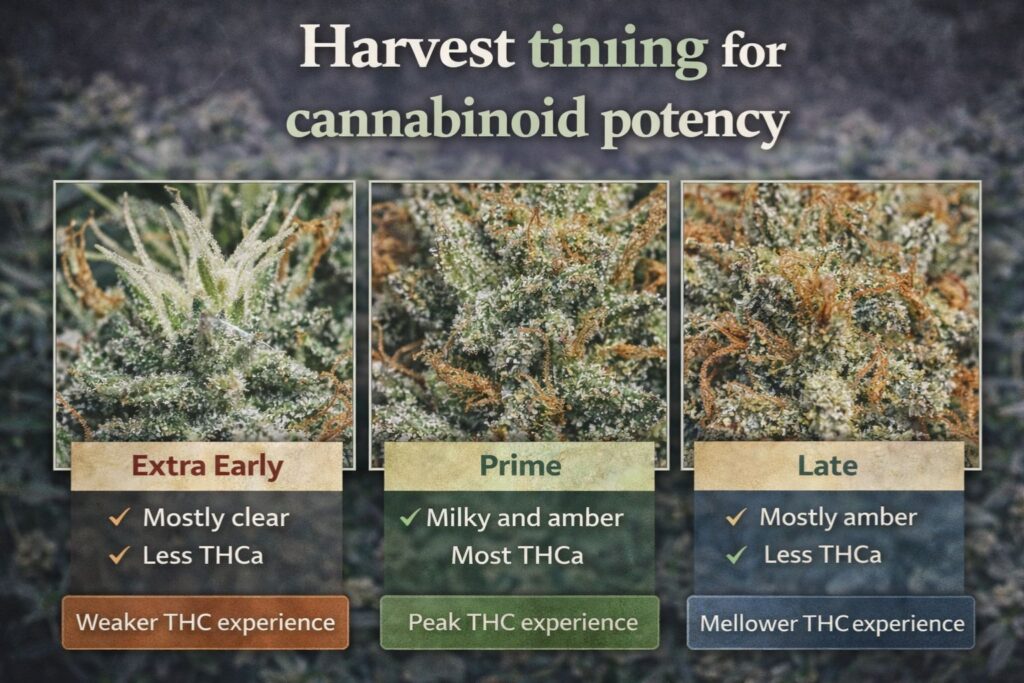

Harvest timing for cannabinoid potency is where TAC becomes tangible. My goal is not “as amber as possible.” My goal is to hit the window where cannabinoids and aroma align with the intended effect.

Here’s what I do:

- Track flowering days by cultivar, but don’t worship the calendar

- Use a loupe and check trichomes on actual calyxes, not sugar leaves

- Note aroma shift: sharp green notes fade, cultivar-specific terpene notes peak

- Watch pistils, but treat them as a secondary indicator

A practical rule I’ve found reliable: if I harvest too early, TAC can look fine but the effect feels edgy and short. If I harvest too late, TAC can remain high, but the profile shifts toward heavier oxidation and the aroma dulls. That’s why harvest timing for cannabinoid potency is a balancing act, not a finish line.

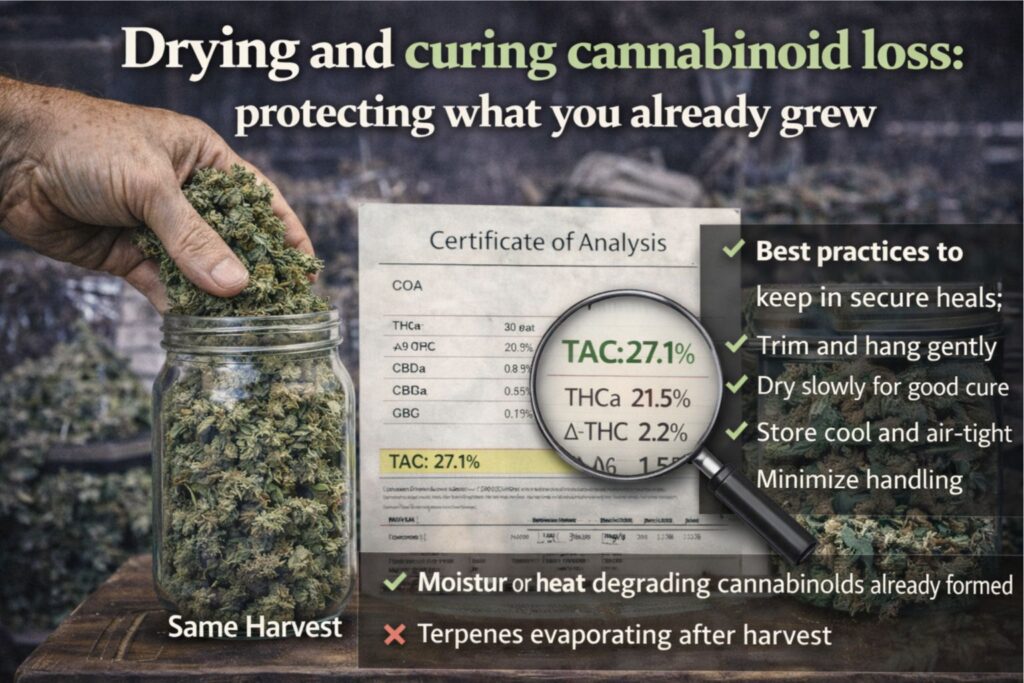

Drying and curing cannabinoid loss: protecting what you already grew

Drying and curing cannabinoid loss is where a lot of growers accidentally throw away their hard work. I’ve had batches that lab-tested well at day 0, then felt noticeably flatter after an aggressive dry. That’s not just terpenes; oxidation and handling matter.

My drying targets:

- 18–20°C with gentle air exchange

- 55–60% RH for a slow dry

- Minimal direct airflow on buds

- Darkness to reduce degradation

I don’t chase a fixed number of days. I go by stem snap and bud feel, then jar with hygrometers. The cure is where I stabilize aroma and reduce harshness while limiting drying and curing cannabinoid loss.

Curing routine that has worked for me:

- First week: burp 1–2 times daily if RH is high

- Weeks 2–3: burp every few days

- After week 3: store sealed, cool, and dark

This is also where I compare jars to learn. If jar A stays louder and smoother than jar B, I look for differences in branch thickness, dry room airflow, or trim timing.

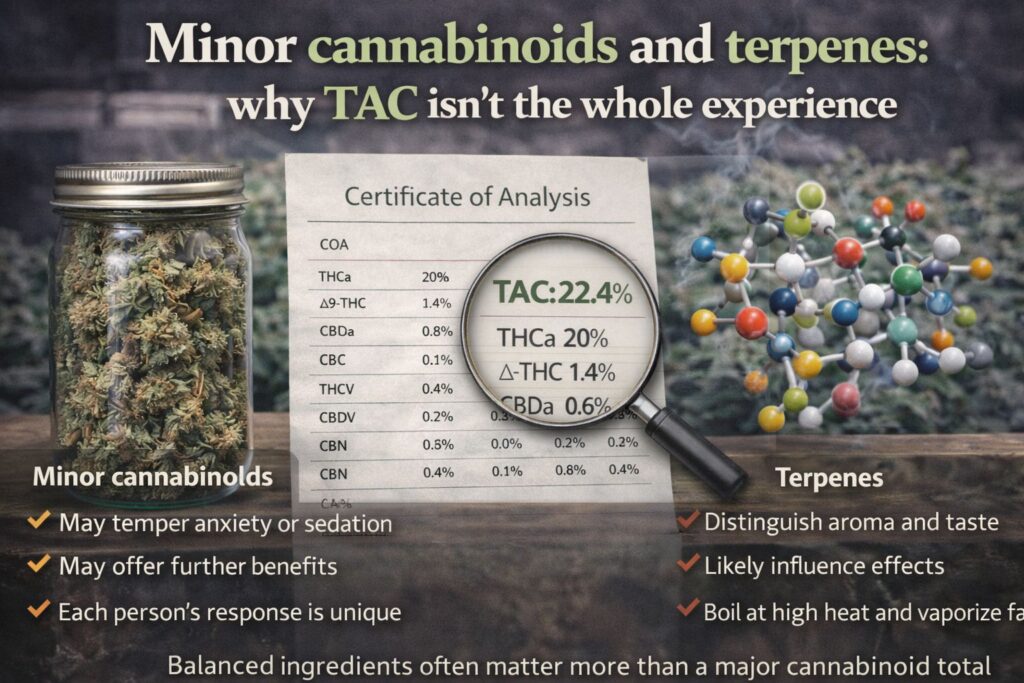

Minor cannabinoids and terpenes: why TAC isn’t the whole experience

Minor cannabinoids and terpenes are why two products with the same TAC can feel different. Terpenes influence aroma and can modulate how the experience is perceived. Minor cannabinoids can shift the effect from clear and functional to heavy and sedating, even when TAC is similar.

In my rooms, terpene preservation starts before harvest:

- Avoid extreme drought stress that stalls terpene expression

- Maintain stable leaf surface temperatures under LED

- Keep late-flower nitrogen reasonable to avoid “green” aroma

Post-harvest, the goal is gentle handling and controlled humidity to protect minor cannabinoids and terpenes. If you’re choosing between batches, don’t ignore freshness. A brilliant COA can’t bring back volatilized aroma.

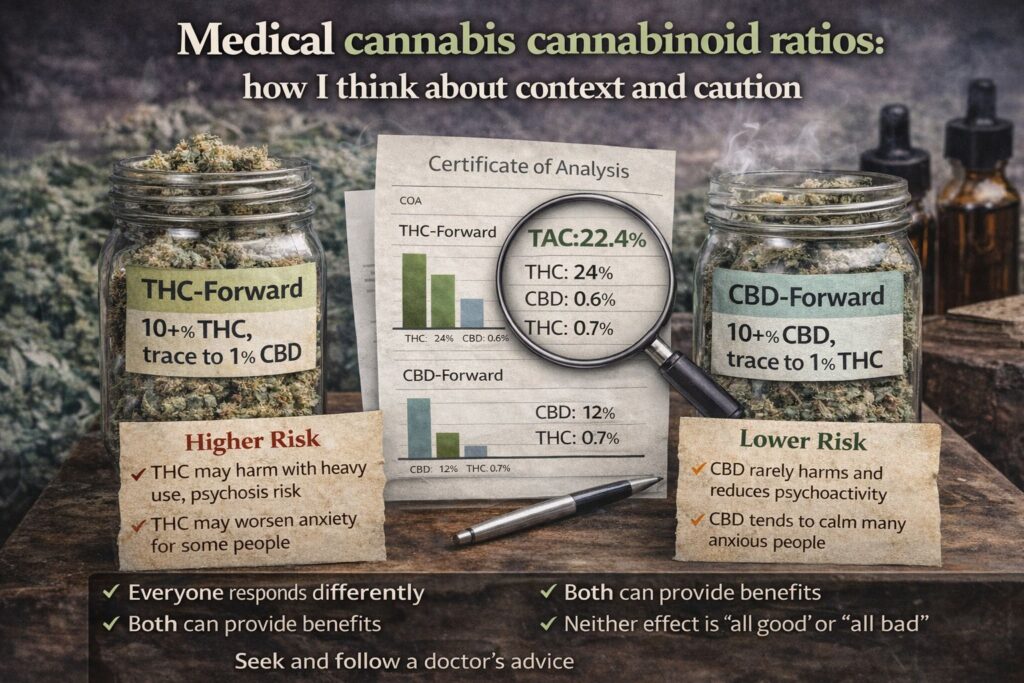

Medical cannabis cannabinoid ratios: how I think about context and caution

Medical cannabis cannabinoid ratios matter because “more” is not always “better.” Different people respond to different THC:CBD balances, and some patients prefer products where CBD is present in meaningful amounts.

I’m not a clinician, and this isn’t medical advice. What I can share is how I see medical cannabis cannabinoid ratios used responsibly:

- Start low, go slow, especially with edibles

- Consider THC:CBD balance if THC sensitivity is a concern

- Keep notes about dose, timing, and effects

- Talk with a qualified healthcare professional where legal and appropriate

In product selection, I use TAC in Cannabis to understand potential cannabinoid availability, then I look at the ratio and the terpene/cannabinoid context. Medical cannabis cannabinoid ratios help frame the conversation beyond one number.

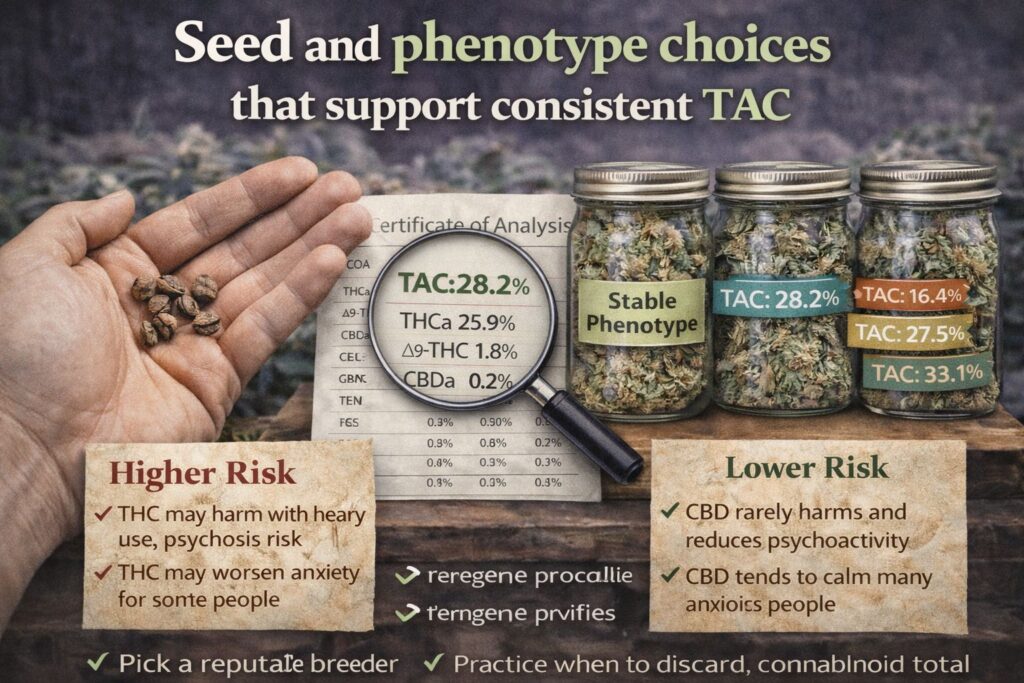

Seed and phenotype choices that support consistent TAC

When I’m choosing seeds, I don’t pick based solely on a single lab test screenshot. I look for stability and repeatability. Here’s my process:

Choosing genetics intentionally

- Decide on the goal: daytime clarity, evening relaxation, balanced functional effect

- Choose cultivar type: indica-leaning, sativa-leaning, or hybrid depending on room constraints

- Consider plant architecture and flowering time for your environment

- Prefer breeders who share selection criteria and testing transparency

If you’re selecting feminized lines, expect less variability than regular populations, but still plan for phenotype hunting. Autoflowering lines can be consistent too, but their fixed lifecycle demands early root health.

Phenotype hunting notes

I keep a simple scorecard:

- Vigor and internode spacing

- Resin development and aroma

- Response to training (topping, low-stress training, trellis)

- Pest resistance and mold tolerance

- Finished flower quality after cure

Over time, this is how I tie cultivation outcomes back to TAC in Cannabis: I’m not just chasing a number, I’m selecting plants that repeatedly finish with strong, enjoyable profiles.

A grower’s checklist for improving TAC consistency

Use this as a quick reference if you’re trying to improve TAC in Cannabis outcomes without sacrificing quality.

1) Confirm you’re comparing the same lab metrics

Use a certificate of analysis walkthrough every time.

2) Stabilize your environment

Target consistent VPD and avoid late-flower swings.

3) Feed for health, not stress

Maintain steady EC, avoid last-minute “boosts.”

4) Dial harvest timing

Revisit harvest timing for cannabinoid potency with a loupe and aroma notes.

5) Slow the dry

Protect against drying and curing cannabinoid loss with controlled RH and gentle airflow.

6) Respect the full profile

Remember minor cannabinoids and terpenes when interpreting tac percentage interpretation.

FAQ: common questions I hear about TAC and lab results

Is TAC the same as THC?

No. TAC is usually broader. It often includes converted acidic cannabinoids via total active cannabinoids calculation, while THC alone can be just the neutral THC line item. This is why tac vs thc labeling exists.

How do I estimate TAC from a COA?

Use a certificate of analysis walkthrough and add the “total” lines if provided. If not, apply total active cannabinoids calculation using THC + (THCa × 0.877), then add other totals if the lab defines TAC that way.

Does higher TAC always mean stronger effects?

Not always. Tac percentage interpretation should include freshness, minor cannabinoids and terpenes, and how the product is consumed. A slightly lower TAC batch can feel stronger if the aroma compounds are preserved.

What should medical users focus on besides TAC?

Medical cannabis cannabinoid ratios and dose consistency are big factors. Consider THC:CBD balance, delivery method, and personal sensitivity, and seek professional guidance where appropriate.

Can my drying process change TAC?

Your dry and cure can influence perceived potency and aroma, and improper handling can contribute to drying and curing cannabinoid loss. Labs measure what’s left in the sample, so post-harvest care matters.

Where does decarb fit into all of this?

Decarboxylation and tac are linked because TAC assumes conversion of acids to neutral cannabinoids. Real conversion depends on time, temperature, and method.

Closing thoughts from the grow room

I like TAC in Cannabis as a tool, not as a verdict. When I use it alongside a careful certificate of analysis walkthrough, it helps me compare batches more fairly and understand why a flower that looks “low THC” can still hit hard. But the most useful improvements I’ve made came from basics: stable environment, healthy roots, thoughtful harvest timing for cannabinoid potency, and a slow dry that limits drying and curing cannabinoid loss.

If you take the numbers seriously, treat them consistently, and respect the role of minor cannabinoids and terpenes, TAC becomes a helpful compass rather than a hype statistic, especially when you pair it with steady cannabinoid profile reporting across runs.