Post-Harvest Handling and Processing of Medical Cannabis: A Comprehensive Guide

Post-harvest handling and processing are critical steps in medical cannabis cultivation. Ensuring proper care during these phases helps to preserve the medicinal qualities of the cannabis plant and maintain its therapeutic efficacy. This guide provides a detailed look at the various steps involved in post-harvest handling and processing of medical cannabis, focusing on methods that optimize the plant’s medicinal properties while adhering to stringent standards necessary for its use in healthcare settings.

1. The Importance of Post-Harvest Handling in Medical Cannabis

Post-harvest handling is crucial in the cultivation of medical cannabis for several reasons:

- Preservation of Cannabinoids and Terpenes: Cannabinoids like THC and CBD, as well as terpenes, are delicate compounds. Mishandling during harvest and post-harvest can result in degradation, reducing the medicinal potential of the plant.

- Consistency and Quality: Medical cannabis patients require consistent dosages for effective treatment. Proper post-harvest practices ensure uniform potency across products.

- Prevention of Contamination: Medical cannabis must be free of pathogens, contaminants, or molds, which can arise if drying, curing, or storage processes are mishandled.

- Patient Safety and Compliance: Medical cannabis must meet regulatory standards for safety and efficacy. Post-harvest handling, therefore, plays a role in ensuring the product’s compliance with healthcare regulations.

2. Harvesting Medical Cannabis: Key Considerations

Harvest timing significantly affects the cannabinoid and terpene profile of medical cannabis. The following aspects are essential to consider for a successful harvest:

- Optimal Maturity: The ideal time for harvesting depends on the type of medical effects desired. For instance, harvesting earlier when trichomes are milky may result in a more uplifting and stimulating effect, whereas later harvesting when trichomes are amber can produce more sedative effects.

- Trichome Monitoring: Growers often use microscopes to check the color and structure of trichomes to determine the optimal harvest window. For medical cannabis, precise timing is vital to ensure the correct cannabinoid profile, which impacts its efficacy for conditions like chronic pain, anxiety, or epilepsy.

- Minimizing Plant Stress: Gentle handling during harvesting is critical to preserving the medicinal properties of the plant. Mechanical or rough handling can damage trichomes and lead to a loss of cannabinoids and terpenes.

3. Trimming: Wet vs. Dry Trimming

Trimming is an essential post-harvest step to remove excess leaves and prepare the cannabis buds for drying and curing. Two common methods are used in medical cannabis processing:

- Wet Trimming: Involves trimming immediately after harvest when the plant is still fresh. Wet trimming is easier, and the buds dry faster since the leaves, which hold moisture, are removed early. This method can be more efficient in large-scale medical operations where fast turnaround is necessary.

Advantages for Medical Use:- Faster drying reduces the risk of mold, a critical concern for patient safety.

- Easier to remove fan leaves and sugar leaves while they are still hydrated.

- Disadvantages:

- May affect the flavor and aroma profile, as terpenes are more prone to evaporation during fast drying.

- Dry Trimming: Involves leaving the leaves on the plant during drying and trimming once the cannabis is partially dried. Cannabinoids and terpenes are preserved by using this approach.

Advantages for Medical Use:- Helps retain terpenes, which have therapeutic benefits like anti-inflammatory and anxiolytic properties.

- Longer drying times can improve cannabinoid retention.

- Disadvantages:

- Increased risk of mold if drying conditions are not carefully controlled.

4. Drying Medical Cannabis: Ensuring Quality and Potency

Drying is the first critical stage post-harvest that has a direct impact on the final medicinal quality of cannabis. The process of drying aids in removing surplus moisture, stopping the formation of mold and maintaining the chemical makeup of the plant.

- Drying Environment: The drying area should have controlled humidity (45-55%), temperature (60-70°F), and air circulation to avoid contamination. For medical cannabis, maintaining a clean and sterile environment is imperative to avoid microbial contamination.

- Hanging vs. Screen Drying: Most growers prefer to hang branches upside down in a controlled environment. Screen drying is also used for smaller buds. However, for medical cannabis, hanging is generally preferred to prevent flattening of the buds and loss of cannabinoids or terpenes due to excessive handling.

- Duration: The drying process typically lasts 7-10 days. Rapid drying can cause degradation of cannabinoids, while slow drying at higher humidity levels can promote mold growth.

5. Curing Medical Cannabis: Maximizing Therapeutic Efficacy

Curing is arguably one of the most important stages in post-harvest handling for medical cannabis. Proper curing enhances the medicinal qualities of the cannabis by allowing chemical processes to continue, resulting in a more refined cannabinoid and terpene profile.

- Why Cure Medical Cannabis?

- Terpene Preservation: Terpenes provide not only aroma and flavor but also specific therapeutic benefits (e.g., myrcene for sedative effects or limonene for anti-anxiety properties).

- Cannabinoid Activation: During curing, cannabinoids like THCA slowly decarboxylate into THC, enhancing their medicinal effects.

- Curing Process:

- Controlled Humidity: Ideal curing conditions involve keeping cannabis in sealed containers at a relative humidity level of around 58-65%. This environment preserves potency while ensuring that buds do not become overly dry.

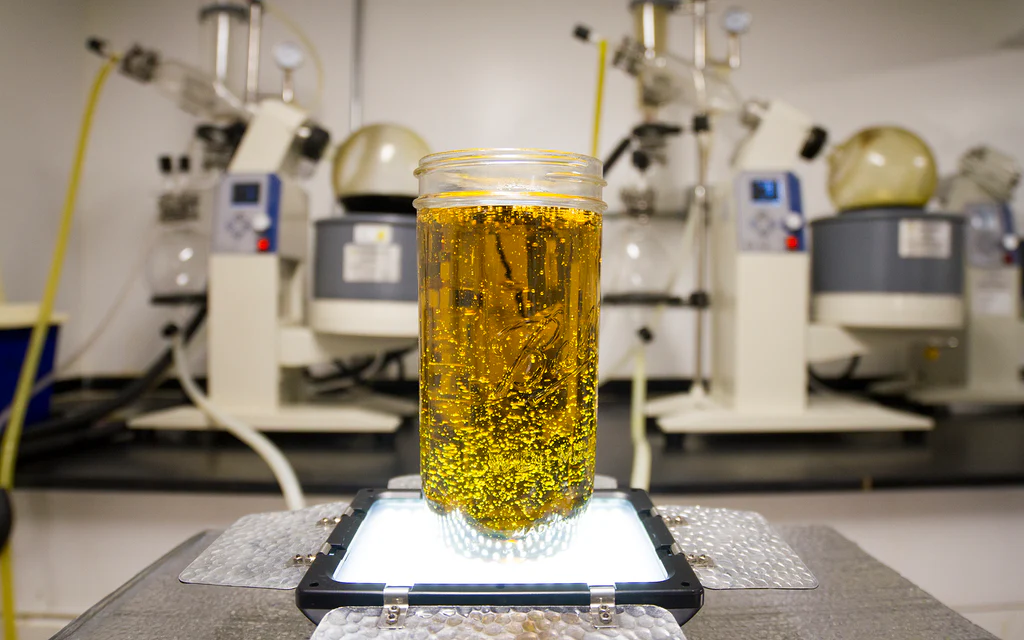

- Curing Containers: Glass jars are preferred, as they are airtight and can be easily burped (opened periodically) to release excess moisture. Medical cannabis processors may also use specialized curing chambers designed to maintain optimal humidity and temperature levels automatically.

- Duration: A slow cure over several weeks is recommended. For medical cannabis, a cure of 4-8 weeks ensures the plant’s medicinal properties reach their full potential.

6. Storing Medical Cannabis: Long-Term Preservation

Proper storage is critical for maintaining the quality of medical cannabis. Poor storage can lead to the degradation of cannabinoids and terpenes, rendering the product less effective for patients.

- Storage Containers: Airtight glass jars or stainless-steel containers are commonly used for storing medical cannabis. These materials prevent light and air exposure, which are two primary factors in cannabinoid degradation.

- Environmental Conditions: Cannabis should be stored in a cool, dark environment with low humidity (ideally 55-62%). Exposure to heat, light, and moisture can lead to the breakdown of THC into CBN (a cannabinoid with less potent effects), as well as promote mold growth.

- Refrigeration and Freezing: In cases where long-term storage is necessary, refrigeration or freezing can be used, though this can sometimes affect terpene profiles. Freezing should be done in vacuum-sealed containers to prevent the formation of ice crystals, which can damage trichomes.

7. Post-Harvest Testing and Quality Control

In medical cannabis production, rigorous testing and quality control measures must be adhered to, ensuring that the product is safe for patient use. Post-harvest testing usually includes:

- Potency Testing: To confirm the concentration of cannabinoids (THC, CBD, etc.) and terpenes, ensuring that medical formulations are accurate and effective for treating specific conditions.

- Microbial Testing: Screening for contaminants like mold, mildew, bacteria, and fungi is critical, as immunocompromised patients could suffer adverse reactions if exposed to these pathogens.

- Pesticide and Heavy Metal Testing: Residual chemicals from pesticides, fertilizers, or other contaminants can be harmful. Testing for heavy metals like lead, mercury, and cadmium is essential to ensure patient safety.

- Batch Consistency: Medical cannabis must be consistent across batches to ensure reliable therapeutic outcomes. Potency and chemical profiles should be uniform, ensuring patients receive the correct dosage in each batch.

8. Processing for Medical Use: Extracts and Concentrates

After post-harvest drying, curing, and storage, medical cannabis is often further processed into various forms such as oils, tinctures, capsules, and topical creams. These forms offer controlled dosing, which is essential for medical cannabis patients.

- Extraction Methods:

- CO2 Extraction: Without the need for solvents, this technique extracts terpenes and cannabinoids using supercritical CO2. It is regarded as one of the safest and most efficient ways to make cannabis oils and concentrates suitable for medical use.

- Ethanol Extraction: Ethanol is commonly used in medical cannabis processing due to its ability to extract a broad spectrum of cannabinoids and terpenes. After extraction, the ethanol is evaporated, leaving a concentrated oil.

- Rosin Pressing: A solventless technique that extracts terpenes and cannabinoids using pressure and heat. While more labor-intensive, it ensures a cleaner product, free from solvents or chemicals, which is highly desirable in the medical field.

- Formulating Medical Products: Once extracted, cannabinoids are formulated into products tailored for medical use. This includes precise dosing for oral tinctures, transdermal patches, or topical ointments designed to treat specific conditions like chronic pain, muscle spasms, or neurological disorders.

9. Packaging and Labeling: Compliance with Medical Standards

Medical cannabis products must adhere to strict packaging and labeling guidelines to ensure safety and regulatory compliance. Key considerations include:

- Childproof Packaging: Medical cannabis is often packaged in tamper-resistant, childproof containers to prevent accidental ingestion.

- Labeling Requirements: Medical cannabis products must be clearly labeled with potency (THC/CBD levels), batch numbers, expiration dates, and usage instructions. Any potential allergens or additives must also be disclosed.

- Tracking and Traceability: In many jurisdictions, medical cannabis is subject to seed-to-sale tracking to ensure transparency and prevent diversion into the recreational market. A distinct identity is given to every batch, enabling quality control or recall procedures.

10. Compliance with Medical Cannabis Regulations

The medical cannabis industry is heavily regulated to ensure patient safety and product efficacy. Compliance with these regulations during post-harvest processing is essential for legal operation and patient care:

- Good Manufacturing Practices (GMP): Medical cannabis processors must follow GMP guidelines to ensure that products are produced consistently and meet quality standards.

- Adherence to Local Laws: Regulations concerning medical cannabis vary throughout locations. Processors must be aware of local requirements for testing, labeling, packaging, and distribution.

- THC Monitoring: For medical products, especially those meant for pediatric or elderly patients, monitoring and controlling THC levels is essential to prevent unwanted psychoactive effects. This requires precise post-harvest processing to ensure that the final product delivers the appropriate therapeutic outcomes without intoxication.

Restrictions on Growing and Using Cannabis in the Medical Field (As a Last Resort)

In the medical field, cannabis use and cultivation are subject to strict regulations and are often considered a last-resort treatment when conventional therapies fail. Below are the key restrictions:

1. Legal and Regulatory Restrictions

- Licensing Requirements: Only licensed medical facilities or individuals (patients and caregivers) in regions where medical cannabis is legalized can cultivate cannabis for therapeutic purposes. Specific permits must be obtained to ensure compliance with local and national regulations.

- Medical Supervision: Medical cannabis is typically prescribed only after other treatments have proven ineffective. Prior to recommending cannabis, healthcare providers must to thoroughly assess the medical history of their patients.

- Disease-Specific Approvals: Some regions restrict medical cannabis use to a limited set of conditions such as epilepsy, chronic pain, or multiple sclerosis. Physicians must document the failure of prior treatments before recommending cannabis.

2. Use as a Last Resort

- Failure of Conventional Treatments: Medical cannabis is often reserved for cases where patients have not responded to standard treatments like pharmaceuticals or therapies. Healthcare providers must exhaust all other treatment options before considering cannabis as an alternative.

- Special Consideration for Vulnerable Populations: In cases involving children, the elderly, or patients with a history of mental illness, cannabis is approached with caution, usually as a final option due to the potential risks associated with THC’s psychoactive effects.

3. Monitoring THC Levels to Prevent Psychoactive Effects

- Low-THC Strains: For medical use, strains with low THC and high CBD levels are often preferred to minimize psychoactive effects. Strains such as ACDC and Charlotte’s Web are commonly recommended for their non-intoxicating properties.

- Precise Dosage Control: Medications derived from cannabis must be carefully dosed to ensure that THC levels are kept below a threshold that could induce psychoactivity. This involves standardized testing and formulation in laboratories to control THC content.

- Ongoing Patient Monitoring: Regular follow-up with patients is necessary to monitor the effects of THC, adjusting dosages if any psychoactive effects arise. Physicians must monitor for adverse reactions such as dizziness, anxiety, or cognitive impairment.

Conclusion: The Importance of Careful Handling, Processing, and Regulation of Medical Cannabis

Medical cannabis has emerged as a crucial alternative for patients suffering from chronic conditions where traditional treatments fail. However, its cultivation, post-harvest handling, processing, and administration demand meticulous attention to ensure that its therapeutic properties are preserved and that patient safety is maintained. This makes it essential for growers, medical professionals, and regulatory bodies to adhere to stringent protocols across all stages, from cultivation to patient administration.

Post-Harvest Handling and Processing: Ensuring Potency and Safety

Post-harvest handling is pivotal in preserving the delicate cannabinoids and terpenes that give medical cannabis its therapeutic potential. Proper harvesting, trimming, drying, curing, and storing ensure that the chemical profile of the plant remains stable, resulting in a product that consistently delivers its medicinal benefits. Drying and curing processes help stabilize the cannabinoids like THC and CBD while preserving terpenes, ensuring that patients receive cannabis with optimal therapeutic efficacy. These steps also prevent contamination from mold or pathogens, which could endanger patient health.

The critical importance of proper drying, curing, and storage cannot be overstated. Inadequate post-harvest care may result in the degradation of cannabinoids, reducing the plant’s potency and ultimately making it less effective for medical treatment. By adhering to best practices for post-harvest handling, cultivators can ensure that medical cannabis maintains its therapeutic benefits and meets the required safety standards for use in healthcare.

Monitoring and Testing for Medical Use

As cannabis transitions from a plant to a medical product, it must undergo rigorous testing to ensure quality and consistency. Testing for potency, microbial contamination, and residual chemicals such as pesticides is mandatory to guarantee that medical cannabis is safe for patient consumption. Medical cannabis products, particularly those intended for vulnerable groups like the elderly or immunocompromised patients, must meet the highest safety standards. Testing also ensures that cannabinoid profiles are consistent, helping medical practitioners prescribe the correct doses and patients receive the appropriate treatment for their conditions.

The cannabinoid profile, particularly the balance between THC and CBD, is central to the medical use of cannabis. For many patients, the psychoactive effects of THC are undesirable, especially in the case of treatments for pediatric or elderly patients. Thus, continuous monitoring of THC levels during post-harvest processing and formulation is vital. This ensures that products remain therapeutic without introducing unwanted psychoactive effects.

Regulatory Frameworks and Restrictions

The legal framework governing the cultivation and use of medical cannabis plays a significant role in ensuring patient safety and product efficacy. In many jurisdictions, strict regulations guide the cultivation, post-harvest handling, and dispensing of medical cannabis. Licensing requirements for growers and dispensaries, as well as rigorous testing protocols, ensure that cannabis remains a viable and safe option for medical patients.

In the medical field, cannabis is often considered a treatment of last resort. Physicians turn to medical cannabis only after conventional treatments have failed to yield results. This conservative approach stems from the need to ensure that patients receive the most effective and least invasive treatments first. As a result, the prescription of medical cannabis must be based on well-documented medical necessity, with careful monitoring of its effects on the patient.

Monitoring THC Levels for Patient Safety

Preventing the psychoactive effects of THC is a key concern in the medical application of cannabis. Patients who need cannabis for its therapeutic benefits, particularly for conditions such as chronic pain, epilepsy, or anxiety, often require formulations with minimal THC content to avoid cognitive impairment or other psychoactive side effects. Monitoring THC levels during extraction, processing, and formulation helps ensure that patients receive a balanced product that delivers the medicinal benefits of cannabis without the potential for intoxication.

This is especially important for vulnerable populations such as children, the elderly, or individuals with mental health conditions, for whom exposure to high levels of THC could exacerbate their conditions. The availability of high-CBD, low-THC strains ensures that these patients can benefit from cannabis without adverse psychoactive effects, making cannabis a safer option for medical treatment.

Final Thoughts

In conclusion, the post-harvest handling and processing of medical cannabis are critical components that influence its safety, potency, and therapeutic effectiveness. Strict adherence to protocols at every stage, from cultivation to formulation, ensures that cannabis can be used as a viable medical treatment. Moreover, regulations governing its cultivation and use ensure that cannabis is prescribed as a last-resort treatment and that THC levels are carefully monitored to prevent unwanted psychoactive effects. As medical cannabis continues to gain acceptance in healthcare, the importance of careful handling and processing remains paramount in delivering safe and effective treatment options for patients.