Why I started paying attention to Plant Growth Regulators

The first time I heard growers argue about Plant Growth Regulators, it was in the most practical setting possible: a trimming table. One pile of cannabis looked picture-perfect—tight buds, short spacing, and a uniform “golf ball” shape. Another pile from the same week smelled louder, burned cleaner, and cured better, but the flowers were a little airier. That contrast pushed me to learn what Plant Growth Regulators actually are, why agriculture uses them, and how they show up in marijuana cultivation—in a spare moment between harvest days.

In plain terms, plant growth regulators are compounds that influence how a plant grows: how fast it stretches, how it branches, how it flowers, and how it ripens. In professional crop production, the goal is predictability. In a weed room, the goal is predictability plus quality. Over time, I learned that the conversation gets confusing because it mixes three different things: natural plant hormones that plants already make, legitimate agronomy tools used responsibly, and a short list of “don’ts” that can contaminate flower and damage consumer trust.

This post is written from my perspective as a hands-on cultivator. It is not legal or medical advice. It is a practical guide to decision-making, with the same mindset I use when I’m shopping genetics, setting a tent’s environment, and deciding what goes into my feed tank.

Plant Growth Regulators in agriculture, without the drama

In mainstream farming, Plant Growth Regulators are used to solve specific problems. Fruit growers manage timing and uniform ripening. Ornamentals producers aim for compact plants that ship well. Cereal crops may use growth regulation to reduce lodging (plants falling over) in high-wind conditions. When I studied this, it helped me separate emotional internet claims from real agronomy.

One of the most commonly discussed examples is gibberellic acid in agriculture. Gibberellins are a class of natural plant hormones that influence elongation and flowering signals. In agriculture, they can be applied to adjust fruit set, berry size, or dormancy timing. The key detail is intent: the compound is being used for a measured outcome, under label guidance, and often with residue limits and withholding periods.

I’ve also seen gibberellic acid in agriculture discussed as a lesson in dose and timing: a little can shift plant behavior, and too much can throw development off.

That same framework can apply to cannabis, but the crop is different. Weed is typically harvested for resin and aromatic compounds, and those traits are sensitive to stress, light, and nutrient balance. So a tool that’s appropriate for a vineyard may be a terrible choice for a flower crop meant for inhalation.

Natural plant hormones vs. synthetic growth control

When growers say “PGR,” they often mean two opposite categories. The first category is natural plant hormones, which include auxins, cytokinins, gibberellins, ethylene, and abscisic acid. Every cannabis plant uses these signals to decide when to stretch, when to branch, and how to respond to day length. When I’m dialing a room, I’m basically trying to create conditions where those natural plant hormones stay balanced.

The second category is synthetic growth control products that push plants toward short, rigid growth. Some of these products are used in ornamentals and turf management. In the cannabis space, my approach is simple: if the product is not clearly labeled for food crops and doesn’t have transparent guidance, it does not belong in a marijuana garden. When consumers ask why some buds look unnaturally dense, my answer is that genetics and environment can absolutely make tight flowers, but shortcuts and contaminants can also create unusual structure with trade-offs in aroma, burn, and overall enjoyment.

A clean middle ground is using legit biostimulants and plant-derived inputs that support the plant without forcing it. I’m careful with this language because the market is messy, but the idea is sound: support the plant’s own signaling instead of trying to override it.

What Plant Growth Regulators mean for cannabis quality

In my grow notes, the “quality” section is more detailed than the “yield” section. For cannabis, quality shows up as aroma intensity, smooth burn, resin texture, and stable cure. Plant Growth Regulators can influence growth patterns, and growth patterns influence the microclimate inside the flower. A tighter, denser canopy holds moisture longer. That can be good for growth early on and a problem late in flower.

This is where internode management becomes a real skill, not just a phrase. Shorter node spacing can mean more bud sites and better light capture, but it also means more leaf mass around developing flowers. If I don’t thin and train, humidity spikes at the bud surface. For me, internode management is mostly environmental: light intensity, day-night temperature difference, and the timing of training.

I also think about canopy stretch control as a series of levers rather than a single product choice. I would rather control stretch by managing PPFD, temperature, and nutrition than by reaching for an aggressive regulator. When I do it right, I keep a uniform canopy without sacrificing terpenes.

The environmental levers I rely on before any “growth regulator” talk

When growers message me asking how to control stretch, I usually answer with numbers, not brand names.

In veg, I run cannabis under a PPFD around 400–600 µmol/m²/s and keep temperatures roughly 75–82°F with lights on. Relative humidity tends to sit around 60–70% early, then I gradually bring it down as the plant gets larger. I use VPD as my main guide; if VPD is too low, the plant stays “soft” and drinks unevenly. If it’s too high, it can stress and stall. This basic climate work often does more for canopy stretch control than anything in a bottle.

At the flip to flower for photoperiod plants, I reduce night temps slightly and watch how the cultivar responds over the first two weeks. If a phenotype stretches hard, I adjust light distance and keep nutrition steady rather than spiking nitrogen. In hydro and coco runs, I watch EC closely. For many rooms, an EC around 1.2–1.8 during veg and early flower is plenty, with adjustments based on cultivar appetite and leaf color. That’s not a promise; it’s a starting range I’ve seen work across marijuana gardens with decent environmental control.

When I’m consistent here, Plant Growth Regulators become less tempting, because I’m getting the structure I want through fundamentals.

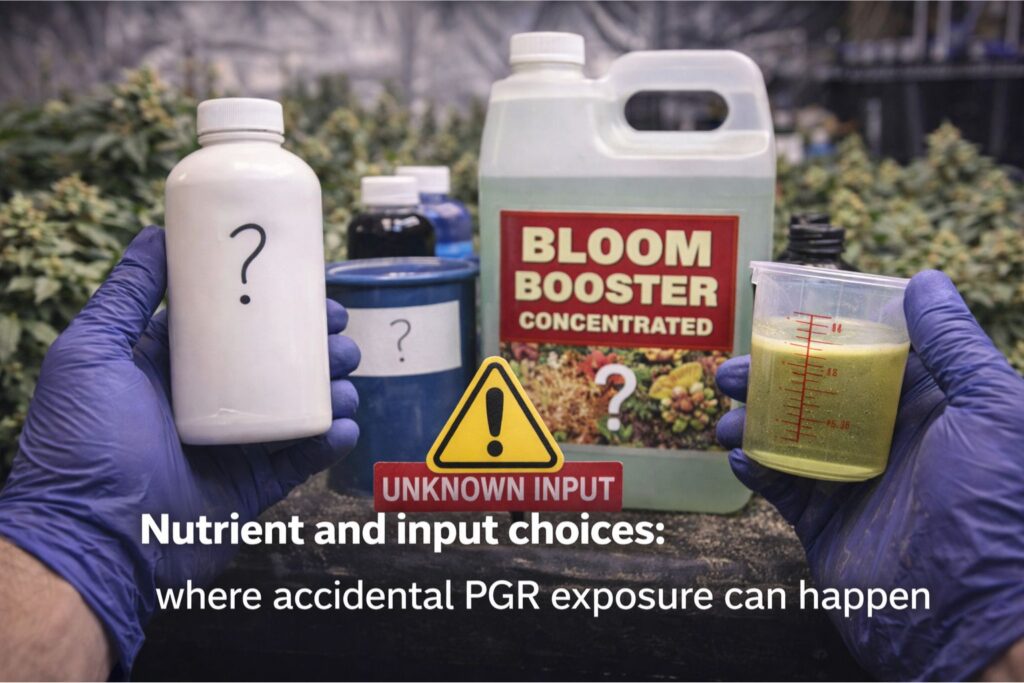

Nutrient and input choices: where accidental PGR exposure can happen

Some of the worst surprises I’ve seen in weed cultivation weren’t from a bottle labeled “regulator.” They came from inputs that were vague, untested, or sourced without transparency. If a label won’t tell me what’s in it, I assume I don’t need it.

For organic-style grows, I’m careful with kelp and alfalfa inputs because they can act like gentle biostimulants. Used responsibly, kelp and alfalfa inputs can support vigorous growth, but they also add complexity: different batches, different extraction methods, and different concentrations of active compounds. I’ve had runs where kelp and alfalfa inputs improved early vigor, and other runs where they made the plant too lush, increasing humidity risk inside dense canopies.

My current practice is to treat these inputs as seasoning, not the meal. I use them with consistent base nutrition and stable irrigation. If the plant looks too dark and soft, I back off. This approach keeps me aligned with natural plant hormones rather than trying to overpower them.

Foliar tools I trust and how I apply them

I’m not anti-foliar. I’m anti-mystery-bottle.

A triacontanol foliar spray is one example of a tool that can be used in a measured, transparent way. Triacontanol is a naturally occurring compound found in plant waxes, and some growers use it to support vigor when applied at low concentrations. The key for me is timing and restraint. If I use a triacontanol foliar spray, it’s early in veg, under low light, with good airflow, and I stop well before flowers are forming. I do not foliar anything late in bloom unless it is a targeted, documented pest response that I’m comfortable with.

I’ll say it again because it matters: a triacontanol foliar spray is not a magic wand. It does not replace light management, root-zone health, or consistent watering.

Beneficial microbes and the root zone: a safer path to vigor

If there’s one place I’ve seen reliable improvements without quality loss, it’s the root zone. Beneficial microbe synergy is real when it is built on simple practices: clean water, oxygenated media, and consistent moisture cycles.

In soil, I focus on structure and drainage so roots can breathe. In coco, I focus on keeping feed consistent and avoiding salt swings. In hydro, I focus on temperature and dissolved oxygen. When those fundamentals are right, beneficial microbe synergy can help with nutrient availability and stress resilience, which indirectly improves structure and flower development.

I also like that beneficial microbe synergy supports the plant’s own signaling rather than forcing a shape. That aligns with my preference to work with natural plant hormones and genetics.

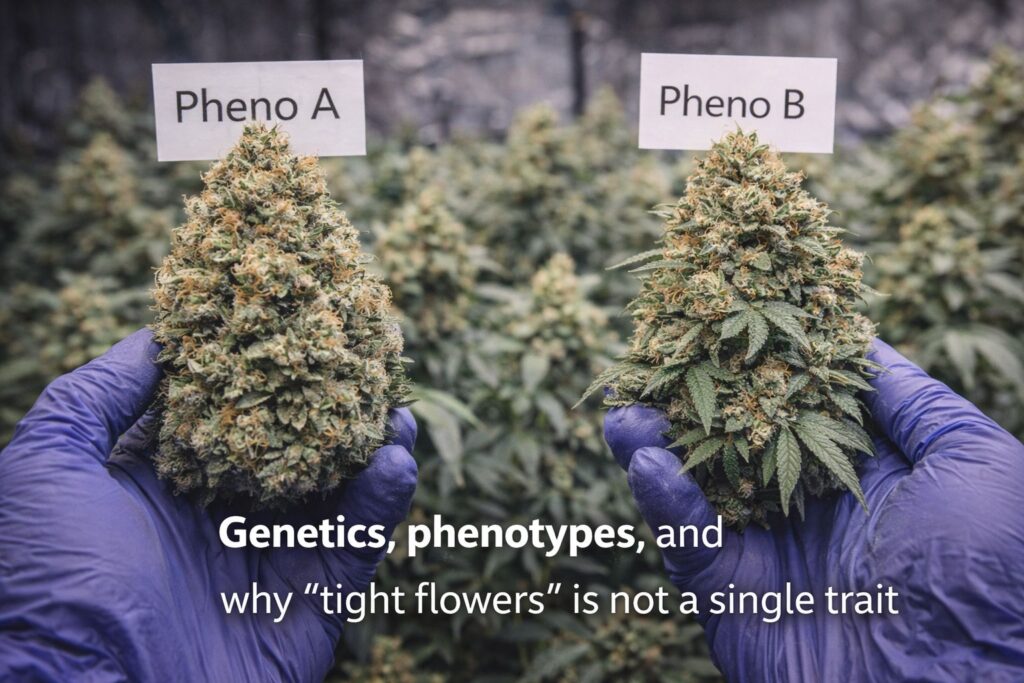

Genetics, phenotypes, and why “tight flowers” is not a single trait

If I’m buying seeds, I’m thinking about structure long before I’m thinking about any regulator. Some lines naturally stack tight. Others build longer spears. Some stretch hard in the first two weeks of flower. That’s why I always pop more than one seed when I can and keep notes on phenotypes.

A lot of “PGR-looking bud” conversations ignore how much internode management depends on genetics. The same room, same light, and same nutrients can produce very different structure across cultivars. That’s normal. When I see a plant with unusually rigid stems, dull aroma, and a strangely uniform bud shape, I start asking questions about the entire input chain.

This is also where seed shopping matters. Reputable seed sources should be clear about whether a cultivar is photoperiod or auto-flowering, and they should set realistic expectations about vigor and stretch. For growers who prefer “set it and forget it,” auto-flowering genetics can simplify timing, but it can also reduce flexibility if the plant reacts poorly to stress. Either way, Plant Growth Regulators are not a substitute for choosing genetics that fit the room.

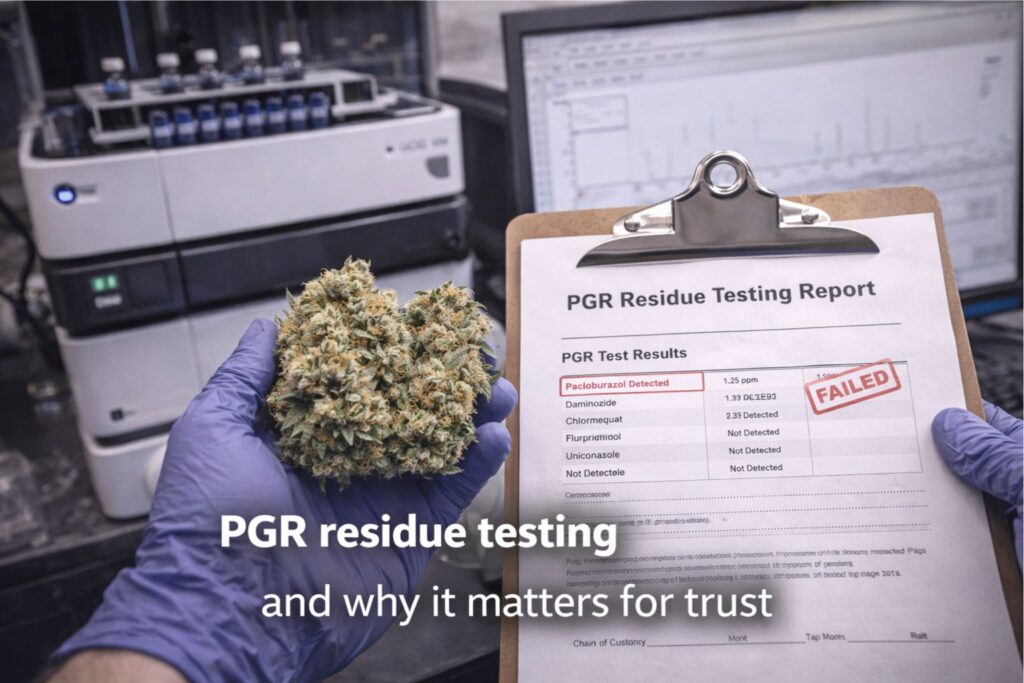

PGR residue testing and why it matters for trust

If there’s a single topic that should unite growers and consumers, it’s transparency. PGR residue testing exists for a reason: some compounds are not appropriate for inhalable flower, and residue concerns don’t go away because the buds look pretty.

From a grower’s perspective, PGR residue testing is also a feedback tool. If a lab panel flags something, the correct response is not denial; it’s investigation. Where did the input come from? Was there cross-contamination? Did a “bloom booster” contain undisclosed actives? Was a foliar applied too late? I’ve seen growers use PGR residue testing as an audit of their whole supply chain, and that’s smart.

If a cultivator is selling flower, PGR residue testing and transparent COAs can build real trust. If a cultivator is home-growing, the same concept applies: stick to known inputs, keep receipts, keep labels, and avoid anything that feels secretive.

Post-harvest contaminant screening: where quality is protected or lost

Most growers focus on the grow and then rush the finish. In my experience, post-harvest is where the “truth” of a crop shows up. Dry too fast and terpenes vanish. Dry too slow and mold risk climbs. Handle buds roughly and trichomes shear off.

I also pay attention to post-harvest contaminant screening when it’s available, especially for commercial operations. Post-harvest contaminant screening is different from potency testing; it’s about making sure the product is clean. Even if a flower tested clean pre-harvest, storage and handling can introduce issues. For me, post-harvest contaminant screening is part of treating cannabis like a real agricultural product, not a novelty.

And yes, the same mindset applies to Plant Growth Regulators. A clean grow is not only about what happens in week three. It’s about what happens from seed to storage.

How grow style and seed type change the conversation

When I’m troubleshooting structure issues, I always ask two questions first: what medium is the plant in, and what type of genetics is it? A photoperiod hybrid can be steered for weeks in veg, while autoflowers commit to their timeline early. The same goes for seed type. Feminized seeds reduce the odds of males, but they don’t remove phenotype variation, so I still watch each plant for stretch and leaf density.

Medium matters just as much. In living soil, I lean on slow nutrition, stable moisture, and beneficial microbe synergy to keep the plant steady. In coco, I rely on frequent irrigation and consistent EC to avoid boom-bust growth that can exaggerate stretch. In recirculating hydro, the room can move fast, so I keep root-zone temperatures controlled and avoid big swings in feed strength. Across all of these, I’ve found the cleanest “regulation” comes from managing inputs and environment, not from forcing the plant with questionable shortcuts.

People also search for practical comparisons like soil vs hydro, and I get why. Soil can be forgiving with pH drift and offers buffering, while hydro can deliver fast growth when dialed but punishes mistakes. Either way, my goal is the same: use light, temperature, and irrigation to keep growth consistent so internode management stays predictable and canopy stretch control stays simple.

How I manage stretch and structure without leaning on regulators

Here’s my personal checklist for canopy stretch control, written the way I actually use it.

- Start with appropriate container size and root-zone oxygen.

- Build structure in veg with topping or low-stress training, not late corrections.

- Keep PPFD steady and increase it gradually, not in sudden jumps.

- Watch day-night temperature differences to influence internode management.

- Keep nitrogen stable at the flip; don’t “feed the stretch.”

- Use trellis support early so the canopy stays even through week three.

- Thin leaves strategically to reduce humidity pockets, especially in dense cultivars.

These steps sound basic, but they work. When the canopy is even, the whole room is easier to manage. When the room is easier to manage, quality improves. That is the outcome I want, whether I’m growing cannabis for personal use or helping a friend troubleshoot a small commercial space.

Regenerative field applications and what cannabis can learn from other crops

I started learning about regenerative field applications long before I used the phrase in a weed context. In row crops, regenerative field applications often mean reducing soil disturbance, keeping living roots in the ground, and building organic matter so the system becomes more resilient.

In cannabis, we don’t always have the same scale, but the principles still help. If soil stays alive and structured, roots thrive. If roots thrive, nutrient uptake stays steady. If uptake stays steady, the plant’s natural plant hormones stay balanced. That reduces the desire to force growth with heavy-handed Plant Growth Regulators.

I’ve also noticed that growers who adopt regenerative field applications tend to be more careful about input transparency. They’re already thinking in systems, so they avoid the mystery-bottle trap.

Seed buying and shipping: practical considerations tied to PGR conversations

People often ask me, “What should I look for when I’m buying marijuana seeds online?” My answer is to look for clarity and consistency.

I want clear labeling about cultivar type, realistic flowering windows, and any known quirks. I also pay attention to how a seller handles shipping: discreet packaging, tracking options, and clear communication about delays. Regional grow laws vary widely, so I never assume a seed purchase is legal everywhere; I encourage growers to learn their local rules before ordering.

This connects back to Plant Growth Regulators in a simple way. When a grower starts with quality genetics and a clear plan, they rely less on shortcuts later. The more predictable the genetics, the easier internode management becomes, and the easier canopy stretch control becomes.

FAQ: common questions I hear about Plant Growth Regulators

Are Plant Growth Regulators always bad in cannabis?

No. Plant Growth Regulators include natural plant hormones and legitimate agronomy tools. When people ask for a single example of a mainstream regulator, I point again to gibberellic acid in agriculture, because it shows how regulated, labeled use differs from mystery inputs. The issue is choosing methods appropriate for an inhalable crop and avoiding inputs with unknown residue risk. I focus on fundamentals first, then only use well-understood tools early in veg.

How can a grower reduce the risk of contaminated inputs?

Buy from reputable suppliers, avoid vague “secret formula” products, and keep labels and batch numbers. If available, use PGR residue testing to audit the full input chain. In commercial settings, post-harvest contaminant screening adds another layer of confidence.

What is the simplest way to control stretch without aggressive products?

Use canopy stretch control through environment and training: steady PPFD, stable temperatures, good trellis support, and disciplined feeding. Combine that with internode management via day-night temperature differences and early training choices.

Do foliar sprays help, or do they risk quality?

Foliar can help when used early and lightly. A triacontanol foliar spray is one tool some growers use conservatively in veg, but it’s not a replacement for root-zone health. If a cultivar already runs dense, foliar late in flower can raise humidity risk and is usually not worth it.

Does germination method affect early growth patterns that people blame on regulators?

It can. When someone asks, “Should I start in a paper towel or direct sow,” I usually answer that consistency matters more than method. I’ve had strong starts with both, but uneven moisture and temperature are common causes of weak seedlings. Stable warmth, clean water, and gentle light help the plant establish balanced natural plant hormones early, which later supports internode management without drama.

Do indica and sativa labels tell you whether a plant will need growth control?

Only partly. In practice, I treat indica, sativa, and hybrid labels as rough descriptors, not engineering specs. Some “indica-leaning” plants still stretch hard, and some “sativa-leaning” phenotypes stay compact under strong light. That’s why I watch the plant and use canopy stretch control methods I can measure, instead of relying on labels or chasing a product claim.

Can organic inputs act like growth regulators?

Yes, in a gentle way. Kelp and alfalfa inputs can support vigor and influence growth patterns, but they can also make a canopy too lush if overused. I treat kelp and alfalfa inputs as minor supplements and rely on consistent base nutrition.

How do regenerative practices fit into this topic?

Regenerative field applications improve resilience by supporting soil biology and structure. In cannabis, that can translate into steadier growth, fewer stress swings, and less temptation to force outcomes with Plant Growth Regulators.

Final thoughts from the grow room

If there’s a single lesson I’ve learned, it’s that the best-looking flower isn’t always the best-smoking flower. My goal is clean, aromatic cannabis that cures well and burns smoothly. Plant Growth Regulators are part of the broader conversation about how we grow marijuana responsibly and how we keep weed trustworthy for the people who consume it.

When I stick to transparent inputs, consistent environment, and solid training, I don’t need shortcuts. I get predictable structure through internode management, reliable canopy stretch control, and a root zone supported by beneficial microbe synergy. And if I ever have doubts, I lean on data—PGR residue testing and post-harvest contaminant screening—because trust is built with proof, not promises.