Table of Contents

Commercial Cannabis Cultivation

Commercial-scale operations are built on the same biological principles as smaller grows, and understanding those fundamentals provides useful context for how large cultivation facilities are designed and managed.

1. Cultivation Types and Infrastructure

Commercial cannabis is cultivated using one of three main systems, each with distinct advantages and cost implications:

a. Indoor Cultivation

- Controlled environment: Light, humidity, temperature, and CO₂ levels are optimized for maximum yields and potency.

- Year-round production: Eliminates seasonal dependency.

- High costs: Requires substantial energy input, HVAC systems, grow lights (HPS or LED), and labor.

b. Greenhouse Cultivation

- Hybrid model: Uses sunlight and supplemental lighting while allowing environmental control.

- Lower costs than indoor: Natural light reduces energy demand, while automation still enables high yields.

- Sustainable option: Many greenhouses now use solar and rainwater harvesting systems.

c. Outdoor Cultivation

- Lowest operational cost: Utilizes natural sunlight and environment.

- Vulnerability to weather and pests: Yields and quality are highly variable.

- Seasonal cycles: Limited to specific harvest windows depending on geography.

2. Key Components of Cannabis Cultivation

a. Genetics and Strain Selection

- Strain choice determines THC/CBD content, yield potential, flowering time, and pest resistance.

- Popular commercial strains include OG Kush, Blue Dream, and Gorilla Glue, which fetch premium market prices.

b. Growth Phases

- Propagation (0–3 weeks): Germination or cloning; optimal for feminized or tissue-culture techniques.

- Vegetative (3–6 weeks): Rapid leaf and branch growth; requires 18+ hours of light/day.

- Flowering (6–10+ weeks): Light switched to 12 hours; buds develop THC and terpene profiles.

c. Nutrient and Water Management

- Precision fertigation (fertilizer + irrigation) is key to consistent quality.

- Hydroponics and coco coir mediums dominate indoor operations, while organic soil is often used outdoors.

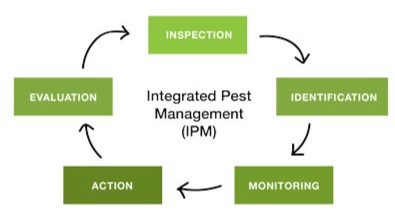

d. Integrated Pest Management (IPM)

- Organic solutions (e.g., neem oil, predatory insects) are preferred to avoid pesticide contamination.

- Testing regulations require minimal microbial, heavy metal, and pesticide residue.

e. Harvest and Post-Harvest

- Harvest timing affects cannabinoid profile and yield.

- Post-harvest includes drying (ideal RH: 55–60%), curing (2–8 weeks for flavor enhancement), trimming, and packaging.

3. Compliance and Licensing

- Cannabis cultivation is tightly regulated, varying by region (e.g., California, Colorado, Canada, Europe).

- Licensing tiers are based on canopy size (e.g., 5,000–10,000 sq. ft. for small-scale, 20,000+ for large-scale).

- Compliance includes seed-to-sale tracking, environmental controls, security, and regular product testing.

- Costs for initial licensure and compliance can range from $20,000 to over $500,000, depending on jurisdiction.

4. Technology in Cultivation

Modern operations leverage:

- Automated climate control: Real-time sensors manage humidity, CO₂, light, and temperature.

- AI & IoT: Machine learning models predict yield, pest risks, and optimize nutrient regimens.

- Data platforms: Track inputs, outputs, and quality metrics across batches.

Automation enhances efficiency and reduces labor costs, which are typically the second-highest expense after energy in indoor grows.

5. Yield and Quality Metrics

- Yield per square foot (Indoor): 40–60 grams (1.4–2 oz) per square foot every 8–12 weeks.

- Outdoor yields: Can exceed 1,000 grams (35+ oz) per plant, depending on genetics and care.

- Cannabinoid content: THC levels above 20% are considered premium. CBD-dominant strains target medical markets.

Higher potency and unique terpene profiles command higher wholesale and retail prices.

6. Profitability Analysis

a. Startup Costs

| Category | Estimated Range (USD) |

|---|---|

| Facility (build/lease) | $100,000 – $2,000,000+ |

| Equipment (HVAC, lighting) | $75,000 – $500,000 |

| Licensing & Compliance | $20,000 – $500,000 |

| Labor & Staff Training | $50,000 – $250,000 |

| Initial Inventory | $25,000 – $100,000 |

| Total | $270,000 – $3M+ |

b. Operating Costs (Annual)

- Indoor: $200–$400/sq. ft.

- Greenhouse: $75–$150/sq. ft.

- Outdoor: $10–$50/sq. ft.

c. Revenue Potential

- Average indoor yield: ~40 grams/sq. ft. per cycle

- 5,000 sq. ft. indoor space = ~200 kg per cycle × 5 cycles/year = 1,000 kg/year

- Wholesale price per gram (varies): $1.00–$3.00/g

- Annual revenue (example): 1,000,000 grams × $2 = $2,000,000

d. Net Profit Margin

- Varies greatly by scale, location, and efficiency

- Average net profit margin: 10–30%

- Efficient indoor or greenhouse operations can net $500,000–$1.5M annually

7. Factors Influencing Profitability

a. Market Conditions

- Prices fluctuate with supply, demand, and regulation (e.g., oversaturation in California led to price drops).

- Export limitations and federal status (especially in the U.S.) hinder broader profitability.

b. Regulatory Environment

- Overregulation or slow licensing processes can restrict market entry.

- Taxes (excise, local, federal) cut into profits often exceeding 30% of gross revenue in mature markets.

c. Brand and Product Differentiation

- Branded cannabis with consistent terpene profiles fetch premium retail prices.

- Value-added products (pre-rolls, extracts, vapes) increase ROI per gram.

d. Vertical Integration

- Companies owning cultivation, processing, and retail reduce overhead and maximize margin.

- Example: Vertically integrated companies can turn $2/g production into $10/g retail sales.

8. Challenges and Risks

- Overproduction: Leads to falling prices and slim margins.

- Regulatory volatility: Legal uncertainties can halt operations or ban products.

- Banking restrictions: In countries like the U.S., federal illegality limits access to traditional banking.

- Security: High-value crops are prone to theft; compliance often requires 24/7 surveillance and fencing.

- Labor shortage: Trained cultivation experts (master growers, IPM specialists) are in short supply.

9. Future Trends

- Global expansion: Legalization in Germany, Thailand, and parts of Africa is driving international cultivation.

- Cannabis 2.0 products: Edibles, beverages, and pharmaceutical-grade extracts are growing in popularity.

- Sustainability: Eco-friendly practices like solar-powered grows and regenerative agriculture are gaining attention.

- Genetic innovation: CRISPR and genomic mapping may allow customization of strains for specific effects or medical conditions.

Conclusion

Commercial cannabis cultivation is a capital-intensive but potentially lucrative venture. Success hinges on optimizing cultivation practices, maintaining compliance, adapting to market shifts, and branding high-quality products. While barriers to entry and risk remain high, disciplined operators can achieve substantial profits especially when leveraging technology, sustainability, and vertical integration.

As the global legal landscape evolves, the cannabis industry continues to mature into a competitive, regulated, and professionalized agricultural sector. With proper planning and execution, commercial cannabis cultivation can be both a profitable business and a key player in the future of wellness, medicine, and recreation.