Why I care about extraction as a cultivator

I’m a cultivator first. My day starts with the room: leaf posture, irrigation timing, and whether the canopy is even enough that my light map still makes sense. But over the last couple of seasons, a bigger slice of my harvest has been purchased for processing instead of trimmed flower. That shift pushed me to learn the language behind Cannabis Distillates and THC Extraction, because the decisions I make in veg and bloom show up later in the oil and on the certificate of analysis.

I’m not writing this to teach anyone how to run extraction equipment. In most regions, making concentrates is regulated, requires trained operators, proper ventilation, and certified systems. What I can share responsibly is the grower-side reality: how I plan a crop for processing, what “good input material” actually means, and how I evaluate distillate products and lab reports without getting lost in buzzwords.

If you’re shopping seeds, growing weed at home where legal, or managing a licensed cannabis garden, the same principle applies: clean, consistent plant material makes everything downstream easier.

What distillate is and what it isn’t

Distillate is a refined cannabinoid oil designed for consistency. In many adult-use markets, that means a high-THC ingredient used for cartridges, edibles, and infused pre-rolls. It’s usually lighter in aroma than live resin products because terpenes and other compounds are separated during processing.

Distillate is not a shortcut for bad cultivation. I’ve seen processors reject biomass for mold, pesticides, or poor handling, and no amount of lab wizardry fixes those problems. From my perspective, Cannabis Distillates and THC Extraction starts in the grow room, not in the lab.

Seed-to-extract thinking: picking genetics that behave predictably

When I’m growing for extraction, I’m less interested in a single showy plant and more interested in repeatable chemistry across a room. That’s why I treat seed selection like a production decision, not just a hobby choice.

My seed-to-extract cultivar selection process looks like this:

- I choose cultivars with stable cannabinoid expression across phenotypes, so blends don’t swing wildly batch to batch.

- I look for plant structure that ripens evenly, because uneven maturity leads to uneven yields and uneven COAs.

- I favor genetics that handle my environment without constant correction, because stress events can shift expression and slow finishing.

- I consider turnaround: autoflowers can be great for fast cycles; photoperiod plants give me more control over veg time and training.

- I buy from seed sources that clearly describe lineage and expected ranges, and I plan around realistic shipping timelines and my local compliance rules.

If you’re comparing seed banks, my advice is simple: prioritize clarity. Look for transparent descriptions, predictable shipping, and support that treats seeds like living genetics, not trinkets.

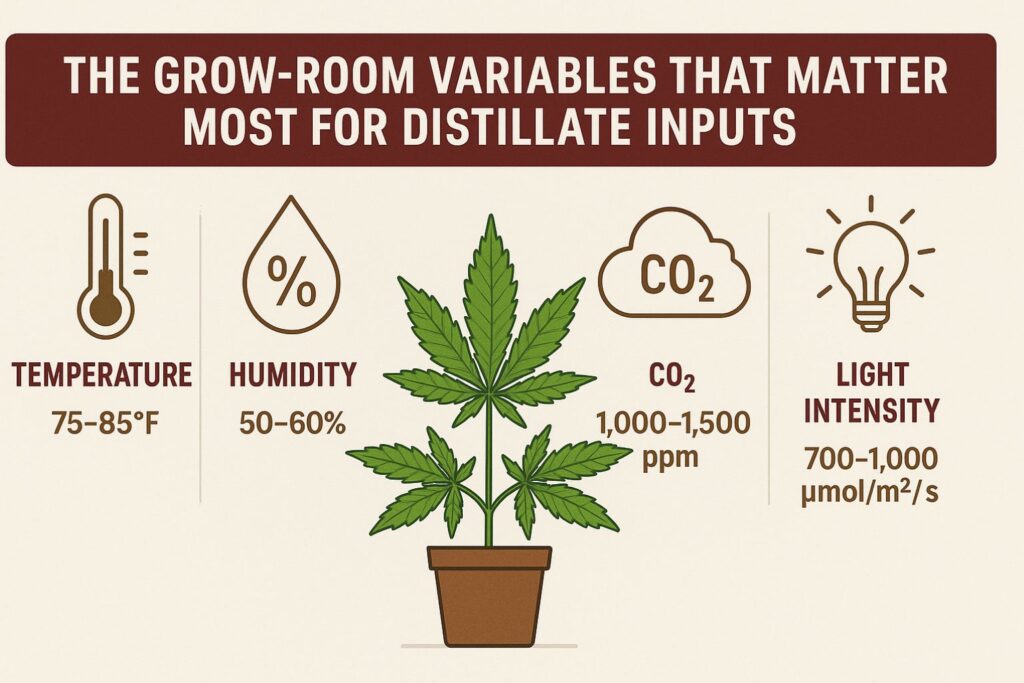

The grow-room variables that matter most for distillate inputs

A processor can refine cannabinoids, but they can’t reverse contamination or sloppy handling. When I’m aiming for extraction-bound biomass, I put my attention on the variables that keep results consistent and protect compliance.

Lighting: mapping PPFD and keeping heat honest

I run LED fixtures and I measure PPFD across the canopy, not just under the center diode. For a productive flowering canopy, I commonly target roughly 700–950 µmol/m²/s in bloom in my rooms, adjusting based on cultivar response and CO2 strategy. I’m also watching leaf temperature because a high PPFD number doesn’t help if the plant is heat-stressed.

What I do every run:

- Map PPFD in a grid so corners aren’t underlit.

- Keep air movement consistent above and below canopy.

- Increase intensity gradually during early flower instead of one big jump.

- Track stretch and internode spacing so I don’t end up with a two-level canopy that matures unevenly.

Humidity, temperature, and VPD: stability beats perfection

I manage temperature and humidity with VPD in mind, but I don’t chase a single “magic” number. In late veg and early bloom, I’m usually comfortable around 24–27°C lights-on with moderate humidity; in late bloom, I tighten humidity down to reduce microbial risk. The key is avoiding big swings that cause stress or invite problems like botrytis.

When a crop is destined for THC oil, I’d rather run slightly conservative conditions than flirt with extremes. A stable room makes a stable harvest.

Nutrition: consistent EC, clean inputs, fewer last-minute moves

Whether you grow in soil or hydro, the biggest favor you can do yourself is consistency. I monitor EC/PPM and pH trends, and I adjust slowly. Sudden feed changes late in flower can create uneven ripening and can complicate what the processor sees in the final batch.

A practical note from my own logs: most of my extraction-bound runs perform best when I keep the root zone healthy and avoid pushing max EC just to chase yield. High yield doesn’t help if the biomass fails testing.

Soil vs hydro: choose the system you can run cleanly

People debate soil vs hydro nonstop. For processing, I care less about ideology and more about whether I can run the system cleanly and repeatably.

- Soil can buffer mistakes and is forgiving with small swings, but irrigation uniformity becomes critical at scale.

- Hydro can be extremely consistent, but it punishes hygiene lapses and demands monitoring discipline.

Either approach can produce excellent cannabis and marijuana biomass for processing if you keep it clean and consistent.

Pest control: prevention first, compliance always

I treat pest pressure as a risk to the whole downstream chain. I scout on a schedule, keep the room clean, and avoid introducing unvetted plants. If I use any input, I assume it could become a testing issue later. That mindset keeps my integrated pest management practical and cautious.

This is where solvent safety compliance starts indirectly: if the crop is clean, the processor has fewer “fix it in the lab” moments and fewer reasons to do aggressive remediation.

Harvest and drying for extraction: I optimize for cleanliness and traceability

When a crop is heading to processing, my harvest priorities change slightly. I still want mature resin, but I also want uniformity, low contamination risk, and clean lot separation.

What “good input” means in practice

Processors talk about THC oil input biomass standards because incoming material drives yield, flavor, and compliance outcomes. When I’m contracted for processing, the buyer’s THC oil input biomass standards are usually written into the purchase agreement, so I treat them like a crop spec, not a suggestion. In the grow room, I translate that into a simple checklist:

- Uniform maturity across the canopy, not just the top colas.

- No visible mold or pest damage, and no questionable material “mixed in.”

- Minimal foreign matter: no zip-tie scraps, glove bits, or media debris.

- Gentle handling to avoid shredding plant tissue and increasing oxidation.

- Clear labeling of lots and dates for batch traceability workflow.

Post-harvest handling: where many batches go wrong

Post-harvest biomass handling is one of those unsexy topics that quietly determines success. I’ve seen great crops lose value because they were dried too fast, stored too warm, or packed without enough airflow. Good post-harvest biomass handling is the cheapest quality insurance I know.

My approach:

- Dry at steady conditions with controlled airflow, avoiding direct fan blast on wet material.

- Keep lots separated and labeled from cut to storage.

- Store in a cool, stable environment to slow oxidation.

- Move material promptly to processing schedules so it doesn’t sit and degrade.

If you’re a home grower producing cannabis where it’s legal, the same principle holds: clean post-harvest biomass handling protects quality, even if you’re not selling to a lab.

Understanding the language around extraction without turning it into a how-to

You’ll hear a few repeated terms in Cannabis Distillates and THC Extraction. Knowing what they mean helps you evaluate products and choose partners, even if you never touch extraction equipment.

Food grade ethanol extraction and winterization, explained at a high level

Food grade ethanol extraction is commonly used because ethanol is a familiar solvent with established handling standards in many industries. Ethanol can pull cannabinoids along with other compounds like waxes and chlorophyll, so processors often use winterization quality control steps to reduce those components before further refinement. When I evaluate a partner, I ask how they document winterization quality control from batch to batch.

As a grower, I don’t need to know every detail. I do need to know the questions:

- What contaminants are tested on the final oil?

- How does the lab manage winterization quality control to reduce waxes without over-processing?

- How is solvent recovery handled in a licensed setting?

Those questions support solvent safety compliance and protect consumers.

Hydrocarbon systems: the safety and compliance lens

A closed loop hydrocarbon system is designed to keep volatile solvents contained and recovered within a sealed process. I’m not giving operational guidance. I’m saying that if you’re evaluating a processor, ask about containment, ventilation, training, and certification. A credible facility will be transparent about safety protocols and will not treat solvents casually.

Distillation: what a short path distillation overview helps you understand

Distillation is a separation method that can help concentrate cannabinoids and remove certain volatiles. A short path distillation overview usually includes the idea of running under vacuum and collecting fractions. I like hearing that short path distillation overview in plain language because it signals the operator understands separation, not just equipment. In practice, that means equipment quality, vacuum integrity, and operator skill influence consistency.

If you want a simple way to assess seriousness, ask how they monitor vacuum pump micron range and how they verify system performance. Even a basic explanation of vacuum pump micron range tells you whether the team is measuring their process or guessing.

Terpenes, flavor, and why distillate often tastes neutral

Distillate tends to be less aromatic because terpenes are volatile and can be separated. Some products add terpenes back in, and that’s where a terpene capture strategy matters. A credible terpene capture strategy also includes contamination screening, because terpenes can carry residues if sourcing is sloppy.

From my side of the fence, I’m watching how my cultivation choices influence terpene integrity:

- Gentle drying protects aroma compounds.

- Avoiding excessive heat stress during late bloom helps preserve volatile expression.

- Harvest timing matters; too early or too late can change the aromatic profile.

If a manufacturer discusses a terpene capture strategy and terpene recovery workflow, I listen for specifics about sourcing, testing, and consistency. A good terpene recovery workflow includes transparency about whether terpenes are cannabis-derived or botanically derived and how they’re tested.

Reading a COA like a buyer, not a fan

I keep a personal distillate COA checklist for anything I’m considering for product work or for evaluating a processor’s output. This is especially important if you’re trying to compare oils sold as “high potency” without meaningful context.

My distillate COA checklist includes:

- Cannabinoid breakdown, not just total THC.

- Residual solvent testing (when relevant).

- Pesticide screening and mycotoxin screening.

- Heavy metals.

- Microbial results where applicable.

- Date and batch identifiers that match the batch traceability workflow.

If the report looks vague, missing, or mismatched, I treat that as a signal to ask more questions. Transparency is part of trust.

Common problems I see and how I troubleshoot them as a grower

I’m not troubleshooting lab equipment here. I’m troubleshooting upstream causes that lead to inconsistent oil.

Distillate clarity troubleshooting starts with clean inputs

When processors talk about distillate clarity troubleshooting, the conversation often circles back to incoming material and handling.

In my experience, these upstream issues are repeat offenders:

- Wet or poorly dried biomass that invites microbial issues.

- Plant matter contamination from rough handling or poor trimming hygiene.

- Mixed maturity levels that create inconsistent chemistry.

- Storage conditions that accelerate oxidation.

I can’t control everything, but I can control how clean and consistent my biomass is before it leaves my facility. That’s the version of distillate clarity troubleshooting I take seriously: prevention.

Potency swings: the hidden cost of inconsistent harvest windows

Cannabinoid oil potency testing doesn’t just measure a number; it measures how repeatable your system is.

If potency swings wildly, I look at:

- Genetic variability (did I pheno hunt too wide for production?)

- Uneven canopy and uneven light distribution

- Nutrition instability late in flower

- Harvesting a room over too long a period without lot separation

When I tighten those factors, potency becomes more predictable. Consistent cannabinoid oil potency testing results are a sign my process is stable.

If you’re buying seeds with processing in mind

People often ask me how to shop for seeds when the end goal includes concentrates or distillates. I treat that as seed-to-extract cultivar selection in the real world: matching genetics to your timeline, environment, and buyer specs.

Practical seed-shopping tips I’d follow again:

- Choose feminized options when you need uniformity and don’t want to spend time sexing plants.

- Consider autoflowers if fast turnover matters, but plan for their fixed timeline and smaller plant size.

- Don’t over-index on indica/sativa labels. Treat them as general descriptors and rely more on cultivar notes, growth habit, and expected finishing time.

- Start with a small run, document results, and scale what behaves predictably.

- Confirm shipping terms, replacement policies, and realistic delivery windows with your chosen seed source.

Seed-to-extract cultivar selection also means respecting your local framework. Always check your regional grow laws, because rules change and differ dramatically by location.

Cartridge formulation considerations when distillate is the ingredient

A lot of buyers experience distillate through vape hardware, so I pay attention to cartridge formulation considerations even though I’m just the grower. If the finished product is a cartridge, the oil has to behave consistently in real conditions: warm cars, cold pockets, and different draw styles. That’s why cartridge formulation considerations show up in procurement calls more often than you’d think.

At a high level, cartridge formulation considerations include viscosity, compatibility with the chosen hardware, and how any added terpenes or minor cannabinoids change flow and flavor. I’m not telling anyone how to mix or manufacture products; I’m describing why consistent input oil and transparent testing matter.

When a brand is serious, they connect cartridge formulation considerations back to documentation: the same distillate COA checklist, the same batch traceability workflow, and clear specifications for any terpene recovery workflow or outside ingredients.

FAQ: real search questions I hear all the time

What is the difference between distillate and live resin?

Distillate is typically refined for consistency and higher cannabinoid concentration, often with a more neutral aroma. Live resin products generally aim to preserve volatile compounds and can have a stronger aroma profile. Both can be made well or poorly; the COA and production transparency matter.

Is Cannabis Distillates and THC Extraction better than other concentrate types?

It depends on the product goal. If you need consistent dosing for edibles or beverages, distillate can be practical. If you want more aroma and a broader profile, other concentrate styles may fit better. I judge by intended use and by the distillate COA checklist.

What should I look for on a distillate COA?

Look for cannabinoid breakdown, contaminant testing, batch identifiers, and dates. A credible report supports batch traceability workflow and makes it easier to compare oils across suppliers.

How do growers influence distillate quality?

Growers influence incoming cleanliness, maturity uniformity, and contamination risk. Post-harvest biomass handling, stable environment control, and disciplined pest prevention all support consistent THC oil input biomass standards.

Do autoflowers work for processing?

Yes, autoflowers can work well for processing when you plan around their timeline and maintain consistency. I still apply seed-to-extract cultivar selection principles and track results batch by batch.

The bottom line from my perspective

When I think about Cannabis Distillates and THC Extraction, I don’t start with machines. I start with canopy uniformity, clean inputs, and traceable handling. If I deliver consistent biomass and I partner with licensed teams that treat solvent safety compliance seriously, everything downstream becomes more predictable: yields, COAs, and product consistency.

In other words, a clean distillate begins with a clean grow.